In the sheet metal manufacturing industry, connection and fixation are extremely critical processing links. In order to ensure that parts can be firmly connected while meeting the requirements of assembly, disassembly and electrical performance, three important processing methods are often used: flanging, riveting/self-clinching and tapping.

Definition

Flanging is a type of stamping process that uses a tooling/mold to bend the edge of a hole or outer edge of a part into a vertical, straight edge. Flanging imparts excellent rigidity to three-dimensional parts, which is often the primary purpose of flanging.

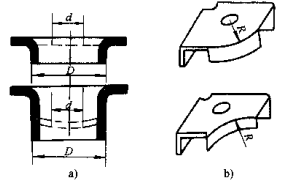

Flanging a hole is called internal flanging, or simply "hole flanging," as shown in picture a). Flanging the outer edge of a part is called external flanging, as shown in picture b.

a) Internal flanging b) External flanging

Flanging differs from bending. In bending, the bending line is primarily straight, with no tangential deformation. In flanging, however, the bending line is curved, and tangential deformation occurs, often the primary deformation.

1. Connecting and Fixing

Connecting Stamped Parts: Flanging allows stamped parts to be connected through welding, riveting, bonding, and other methods to form a single unit.

Alternative to Welded Flanges: Particularly in pipeline construction, flanging can be used in conjunction with loose-fitting flanges to replace traditional welded neck flanges, reducing costs and speeding up installation.

2. Improving Product Performance and Appearance

Enhancing Structural Strength: Flanging increases structural rigidity, improving its resistance to impact and deformation.

Improving Fluid Flow: In pipe connections, flanging creates a smoother transition, reduces fluid resistance, and prevents dirt accumulation.

Enhancing Appearance: Flanging creates a neater, more aesthetically pleasing edge.

3. Facilitating Subsequent Processing

Preparing for Threaded Holes: After flanging, threaded holes can be machined into the flange, facilitating the installation of bolts and other components.

Preparing for Subsequent Processing: Flanging provides a press-fit edge for subsequent shaping, riveting, and other processes.

4. Saving Costs

Reducing Material Costs: When using loose-fitting flanges, flanging allows the use of lower-grade materials, reducing overall costs. Improved production efficiency: Flanging can simplify subsequent processing steps and improve production efficiency.

Notes

Appropriate Material Selection: Choose materials with good plasticity, such as mild steel or aluminum; stainless steel is prone to cracking.

Appropriate Plate Thickness: Too thin will crack, and too thick will be difficult to flip. The recommended flange height is 1.5-2.5 times the plate thickness.

Good Hole Design: Holes should not be too close to the edge, and multiple holes should be spaced sufficiently apart.

Precise Mold: It is recommended to use a flanging mold to avoid flipping too deep at one time.

Meticulous Post-Processing: Deburr after flanging, and ensure a sufficient number of thread turns during tapping.

Definition&Advantages

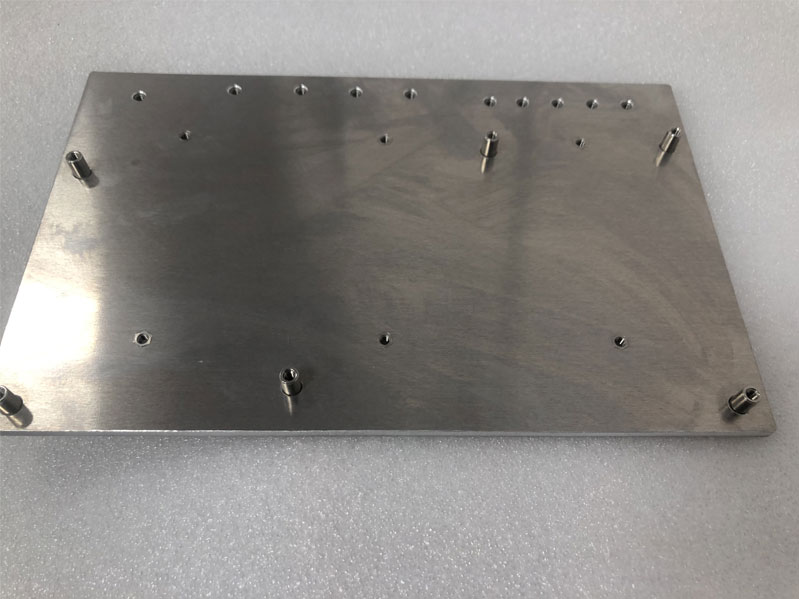

Compression riveting is a method of fasteners, such as nuts, studs, and screws, that are forced into sheet metal using pressure. The fasteners are embedded in the metal material through specialized structures (such as barbs, knurling, or toothed rings), achieving an integral fixation to the sheet metal.

Function

1. Pressure riveting securely connects the rivet to the sheet through plastic deformation, creating a mechanical interlock and providing a high-strength connection.

2. It improves production efficiency and is generally faster and more efficient than other joining methods, especially in mass production.

3. Pressure riveting can replace some fasteners such as screws and nuts, simplifying the assembly process and reducing the number of parts.

4. It is suitable for a variety of metal materials, such as mild steel, aluminum alloys, and copper, and for sheet metal of varying thicknesses.

5. It is easy to install, typically requiring only simple pressure equipment, without the need for additional welding or tapping.

Notes:

The material must have a certain degree of plasticity (typically aluminum, stainless steel, or mild steel).

The riveting equipment must apply uniform pressure to avoid damaging the parts.

Definition

Tapping, also known as threading, it refers to the process of cutting one or more tooth profiles into the wall of a drilled hole. The result is a fastening thread that is matched with external threaded parts to form a standard mechanical part connection method.

Function&Advantages

1. Provides threading functionality, enabling removable connections between parts.

2. Suitable for thick or medium-thick plates or flanged holes.

3. Easy processing and low cost.

4. Can create threads directly on metal plates.

5. High precision, suitable for automated assembly.

Notes:

Shallow threads may result in insufficient strength.

Requires certain plate thickness (usually ≥1.5mm).

Riveting suitable for frequent assembly and disassembly or high loads.