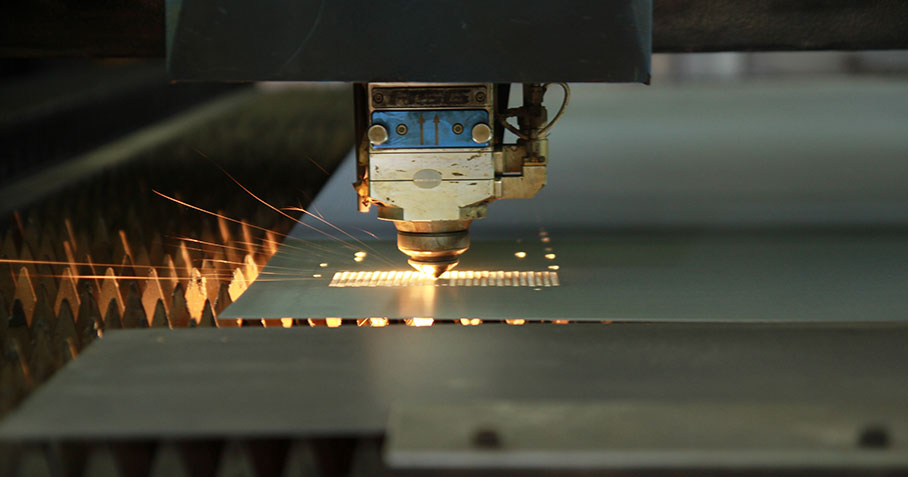

Sheet metal laser cutting is a manufacturing process that uses a laser to cut materials, specifically sheet metals. It is a non-contact cutting method, which means that the laser beam does not physically touch the material during the cutting process. As a professional company of laser sheet metal fabrication, HSJ provides you with high-quality sheet metal laser cutting service.

Using CAD files to guide cutting designs from specific materials, laser plate cutting is a precise method. There are three steps for sheet metal laser cutting process.

Step 1. Prepare your work

You send the artwork to us, and we will check whether the laser cutting machine and the material you want to cut can be used normally. The machine reads vector strokes of hairline thickness in red or a thin line as thin as your desire.

Step 2. We configure the settings of the laser cutting machine

We put the material of your choice into our machine and configure the machine to cut your artwork. According to your material, we adjust the power, speed and frequency.

Step 3. Making your work

Then, the machine will cut out the drawn parts following the path of the drawn stroke.

Shenzhen HSJ Metal Fabrication Co., Ltd. offers a high-quality sheet metal laser cutting service. Our sheet metal laser cutting service can cover a vaterity of materials, including SGCC galvanized plate, SECC electrolytic plate, SUS stainless steel (model 201 304 316, etc.), SPCC iron plate, white copper, red copper, AL aluminum plate (model 5052 6061, etc.), SPTE, spring steel, manganese steel.

HSJ Metal Fabrication’s sheet metal cutting service can provide customers with fast and efficient laser cutting. It is an ideal solution for cutting customized shapes from plates and sheets economically without the need for expensive tools.

The turnaround time is very fast, so we can also handle small batches and large batches of production. Our advanced numerical control machines help to achieve precise cutting of metal shapes and blanks. The metal cutting machine can cut thin metal into a certain shape. A small beam kerf allows for very intricate designs to be cut.

When performing the laser cutting process, we can fully control the beam intensity, heat output and duration. So this process is highly reliable and so helps to significantly avoid errors and reduce material waste.

The sheet metal cutting service offered by HSJ Metal Fabrication includes custom metal duct fabrication. HSJ Metal Fabrication performs precision laser cutting processes on sheet metal according to specific customer requests.

Our CNC machines guarantee the exact result you need. we are able to provide a custom laser sheet metal fabrication service alongside constant support from our Technical Department that checks the making of sheet metal every step of the way.

If you are looking for a reliable laser cutting manufacturer, HSJ can be your best choice. We have our own designer team and professional service will get back to you. Please contact us in any time.

OEM Laser Cutting custom computer case sheet metal part,computer enclosure Computer host shell, computer chassis, accessories, custom sheet metal cabinets, various of electronic sheet metal parts.

Thickness:0.1mm—20mm

Tolerance: + / - 0.02 mm - 0.1 mm

Equipment: HSG(HS-G3015A) laser machine

Production capacity: 10-10000000pcs

Thickness:0.1mm—20mm

Tolerance: + / - 0.02 mm - 0.1 mm

Equipment: HSG(HS-G3015A) laser machine

Production capacity: 10-10000000pcs

The main types of sheet metal laser cutting methods commonly employed for sheet metal cutting are as follows:

CO2 Laser Cutting:

CO2 laser cutting, powered by a carbon dioxide gas mixture, has long been the workhorse of sheet metal cutting. It offers versatility and is well-suited for a variety of metals, including stainless steel, mild steel, aluminum, and non-ferrous materials. CO2 lasers provide high-quality cuts with excellent edge finishes and minimal heat-affected zones. They are effective for a broad range of sheet metal thicknesses, making them a popular choice in many industries, such as automotive, aerospace, and manufacturing.

Crystal Laser Cutting (Nd:YAG Laser Cutting):

Often referred to as crystal laser cutting, Nd:YAG lasers employ a solid-state crystal, specifically neodymium-doped yttrium aluminum garnet, as the active medium. While not as prevalent as CO2 or fiber lasers, Nd:YAG lasers have their niche in sheet metal cutting. They are particularly suitable for thin sheet metals and exhibit good cutting quality. Nd:YAG lasers find applications in specialized fields, including electronics, jewelry, and medical devices. They offer precise cutting capabilities for intricate designs and are adept at handling reflective materials.

Fiber Laser Cutting:

Fiber laser cutting has gained significant traction and popularity in recent years, revolutionizing the sheet metal cutting landscape. These lasers utilize optical fibers doped with rare-earth elements, such as erbium, ytterbium, or neodymium, to generate the laser beam. Fiber lasers excel in high beam quality, enabling them to achieve exceptional cutting speeds with excellent accuracy and reliability. They are highly efficient and exhibit superior energy conversion compared to other laser types. Fiber lasers are especially effective for thin to medium sheet metal cutting, including stainless steel, aluminum, brass, and copper. Their capabilities make them indispensable in industries like automotive, electronics, and fabrication.

Lasers are widely used for sheet metal cutting due to several advantages they offer over traditional cutting methods. Here are the key reasons why lasers are preferred for sheet metal laser cutting:

Precision and Accuracy: Lasers provide exceptional precision and accuracy in cutting sheet metal. They produce a concentrated and highly focused beam of light that can be controlled with great precision. This allows for intricate and complex cuts, sharp corners, and fine details, enabling manufacturers to achieve high-quality results.

Non-Contact Process: Laser cutting is a non-contact process, meaning that the laser beam does not physically touch the material being cut. This eliminates the risk of tool wear or material deformation that can occur in traditional cutting methods. As a result, laser cutting minimizes the need for secondary processing or finishing operations.

Versatility: Lasers offer versatility in cutting a wide range of sheet metal materials. They can cut through various metals, such as stainless steel, mild steel, aluminum, brass, and copper. Additionally, lasers can be used for cutting non-metallic materials like plastics, wood, and composites, expanding their applications across different industries.

Speed and Efficiency: Laser cutting is a rapid and efficient process. Lasers can achieve high cutting speeds, enabling faster production rates compared to conventional cutting methods. The heat generated by the laser beam allows for quick melting, vaporization, or ablation of the material, resulting in efficient cutting operations.

Complex Geometries and Intricate Designs: Laser cutting offers the ability to cut intricate shapes and complex geometries with ease. The flexibility of laser technology allows for the precise cutting of patterns, contours, and intricate designs that may be challenging or time-consuming with conventional cutting methods. This capability is particularly valuable in industries such as automotive, aerospace, and electronics, where intricate components are common.

Minimal Heat-Affected Zone: Laser cutting produces a narrow kerf and a minimal heat-affected zone (HAZ) around the cut. The concentrated heat input and rapid cooling minimize thermal distortion, reducing the chances of material warping or damage. This is especially crucial when working with heat-sensitive materials or when tight dimensional tolerances are required.

No, and this is one of the greatest advantages of all. It is a non-contact process and uses a beam highly precise on the focused area. Thus the heat damage is minimal to the surrounding area of the material.