CNC machining, which stands for Computer Numerical Control machining, is a highly automated manufacturing process used to create precise and intricate parts and components. In CNC machining, computer programs control the movements of cutting tools and machinery to shape raw materials, such as metal or plastic, into finished products. This process offers exceptional accuracy, efficiency, and repeatability, making it a widely used method in various industries for producing components with intricate geometries and tight tolerances. CNC machining encompasses a range of techniques, including milling, turning, drilling, grinding, and more, providing versatility for different manufacturing needs.

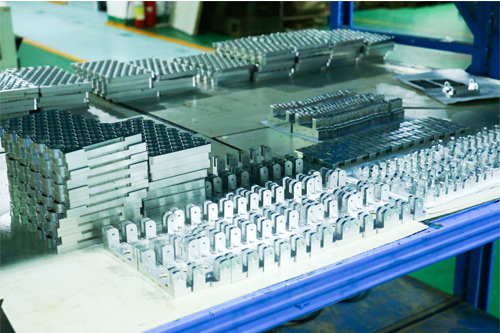

HSJ is a professional CNC metal parts manufacturer. Leveraging advanced technology and a skilled workforce, HSJ specializes in crafting CNC-machined metal parts that adhere to the stringent standards of various industries.

HSJ Metal Processing, as a professional CNC metal parts manufacturer, possesses the capabilities to fulfill your requirements for CNC steel parts through the following processes:

CNC Milling: Employing a subtractive manufacturing approach, this process utilizes both three-axis and five-axis index milling techniques to precision-cut solid plastic and metal blocks into their final parts.

CNC Turning: Integrating the functionalities of a lathe and milling, this process excels in machining parts directly from metal rods, incorporating embedded features with precision.

CNC Drilling: Executed on lathes and mills, this process involves fixing the workpiece in place. The center of the knife aligns with the center of the hole, rotating to produce a meticulously crafted round hole.

Choose HSJ Metal Processing for your CNC steel parts requirements, where our comprehensive capabilities in milling, turning, and drilling ensure the efficient and precise fabrication of components.

Precision CNC metal parts processing involves a series of carefully orchestrated steps to achieve accurate and finely crafted custom CNC metal parts. The typical working steps in this process are as follows:

Design and Programming:

Engineers create a detailed 3D model of the desired metal part using Computer-Aided Design (CAD) software.

The CAD model is translated into CNC code (G-code), which serves as the set of instructions for the CNC machine.

Material Preparation:

The raw material, often metal bars, sheets, or blocks, is selected based on the design requirements.

The material is securely fixed onto the CNC machine, ensuring stability during the machining process.

Machine Setup:

Cutting tools and other necessary equipment are installed on the CNC machine according to the programmed specifications.

Workholding fixtures are put in place to secure the material during machining.

CNC Machining Operations:

CNC Milling: The cutting tools rotate on multiple axes to remove material and create complex shapes.

CNC Turning: The material rotates while cutting tools shape it into cylindrical or tapered forms.

CNC Drilling: Precise holes are created by aligning the center of the tool with the center of the hole and rotating.

Quality Control:

Throughout and after machining, quality control measures are implemented to ensure the final parts meet specified tolerances.

Inspection tools such as coordinate measuring machines (CMM) may be used to verify dimensions.

Surface Finishing (Optional):

Depending on the application, additional processes like polishing, coating, or heat treatment may be applied to enhance the surface properties of the metal parts.

Final Inspection and Packaging:

The finished parts undergo a final inspection to ensure they meet all quality standards.

Approved parts are carefully packaged for shipping or further assembly.

Precision CNC metal parts processing is a meticulous and controlled sequence of steps, designed to deliver components with exceptional accuracy and reliability for a wide range of industries. HSJ stands out as one of the most professional CNC machining parts suppliers, distinguished by its commitment to precision engineering and delivering top-tier components. If you are looking for a reliable,

| CNC Metal Parts Tolerances | |

| Maximum Parts Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe parts up to 62” (1,575 mm) length and 32” (813 mm) diameter |

| Lead Time | Sample Normally 3-5 Days,(need confirm) Mass order: Normally 7-35days(need confirm) |

| General Tolerances | Metals parts will be held to +/- 0.005" (+/- 0.127 mm) ,as ISO 2768 standard,unless otherwise specified. Plastics and composites will be +/- 0.010” |

| Precision Tolerances | HSJ manufacture can do as per your drawing specifications including GD&T callouts |

| Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

| Threads and Tapped Holes | HSJ can meet all standard thread size. Also accept customized threads, along with manual quote review. |

| Edge Condition | Sharp edges will be deburred by default,for safety assembly |

| Surface Finish | As customized request,below for reference: Sandblasting, shot blasting, grinding, tumbling, polishing, brushing, spraying, painting, oiling, blackening, anodizing, electrochemical polishing, electroplating etc. |

HSJ Metal Fabrication is a machined metal parts supplier and works with a large selection of metal and plastic. As one of the highly acclaimed machined metal parts suppliers and cnc machining metal parts suppliers, we have stocked common kinds of materials and as a machined metal parts supplier, we can source for desired materials and provide machining options with customized raw materials that will match the application of your project. So you can choose from a broad range of metals and plastics in HSJ.

(1) Materials for CNC machining metal parts: Aluminum, aluminum-magnesium alloy, aluminum zinc alloy, copper, steel, iron, etc.

(2) CNC plastic: ABS, PMMA, PP, PC, POM, nylon, bakelite, etc.

HSJ is a professional CNC metal parts manufacturer and supplier. If you are looking for a reliable CNC metal parts manufacturer, HSJ can be your best choice. We have the confidence to provide the best products for you. Please contact us at any time if you need us. Since 2015, 8 Rich experience engineers and 5 QC members to guarantee quality. Mr. Li, the president, and top leader of our manufacturing, with 20 years of rich experience from workshop front line, to manager work, then factory CEO. After raw accumulation experience, Finally successfully starts HSJ factory Day and night.

Reasonable price.

All the quotations are based on market material price, exchange rate, and work labor per hours consideration .so that to make sure the quotation's accurate and right.

Sample/MP lead time:

sample:3-7days normally

Mass order: (normal time)

200-500:7-15days

500-2000:15-25days

2000-10000:25-35days

Original manufacture.

We focus and specialized in sheet metal fabrication and CNC machining parts direction only.

Energetic Team

Every year the festival celebration, team travel, table meeting party, etc, makes the team energetic, so that to relax and can inspire new idea and have good mood action on work.

One-stop Services

When got an idea or finished design, the first action is to update the drawing .then we can help you confirm data, evaluate the application, feedback confirmation, sample produce, QC, Evaluate order, QC, Mass order, and QC.the project summary, etc.

Quick Response and professional confirmation

After receiving the inquiry, will Response quickly to confirm the data, submit it to our quotation team, feedback on the result.

QC teamwork

All the material, process, labor time, QC make sure the qualified product .and inspection from Material,semi-product to finished product. After QC signs, the goods will go to the next process.

OEM, ODM Custom

Customized experience including material choice, solution match, Surface treatment evaluation, Logo, package way, delivery method, etc.

Delivery method:

Can choose below

By Express, around 3-5days

By Air, around 5-7days

By train, around 25-35days

By sea, around 35-45 days

Energy product hand model, LED light housing, mobile power housing, solar equipment, etc.

Medical device model: X-ray machine, Hemodialysis instrument, monitor, foot health instrument.

Industrial hand model: pipeline testing equipment, automatic meter testing equipment, intelligent robots, bearings, casings, etc. Aerospace, automotive field.

Advantages of the three-axis CNC: The machine can only realize the movement of the tool in space rectangular coordinate system by interpolation of three linear axes of X, Y and Z, which is suitable for product processing with less surface.

Material: aluminum alloy, copper,

Surface treatment that can be done: anodized black, dusted, electroplated, etc.

Accuracy of reach: ±0.1

A CNC (Computer Numerical Control) system is a complex manufacturing control system with key components:

Programmable Logic Controller (PLC): Processes G-code/M-code and translates it into signals.

Processor (CPU): Executes instructions, interpreting G-code commands.

Control Panel/Console: User interface for program input, machine control, and monitoring.

Axes Controllers: Manage the movement of machine components along specified axes.

Drive Units and Motors: Convert electrical signals into mechanical motion for precise movement.

Feedback Systems: Provide real-time position and speed feedback for accuracy.

Tooling: Cutting tools and accessories controlled by the CNC system.

Emergency Stop (E-stop): Halts machine operations in emergencies.

Coolant System: Manages heat and removes debris during machining.

Spindle: Rotates and controls cutting tool speed and direction.

Understanding these components is crucial for effective CNC machine programming and operation in manufacturing.

A CNC (Computer Numerical Control) machine operates by translating a 3D design created in CAD (Computer-Aided Design) software into G-code and M-code. The CNC system then executes this code to precisely control the movement of cutting tools on a workpiece. The process involves loading the program, securing the workpiece, initializing the machine, and executing cutting operations. Feedback systems monitor and adjust the machine in real-time for accuracy. CNC machines offer high precision and efficiency, making them essential in various manufacturing applications.

In CAD (Computer-Aided Design) drawings, there are three main types of tolerances:

Dimensional Tolerance:

Dimensional tolerance specifies the allowable variation in the size of geometric features such as length, width, and height. It ensures that the actual dimensions of the manufactured part remain within acceptable limits.

Geometric Tolerance:

Geometric tolerance controls the form, orientation, and location of features. It includes specifications such as flatness, straightness, circularity, concentricity, and position. Geometric tolerances provide a more comprehensive understanding of the part's shape and relationships between features.

Surface Finish Tolerance:

Surface finish tolerance defines the acceptable variations in the texture or smoothness of surfaces. It is crucial for parts where the surface quality affects functionality, aesthetics, or interactions with other components.

These tolerances are essential in CAD drawings to ensure that the manufactured parts meet design requirements and function as intended. They help maintain consistency and quality in the manufacturing process.