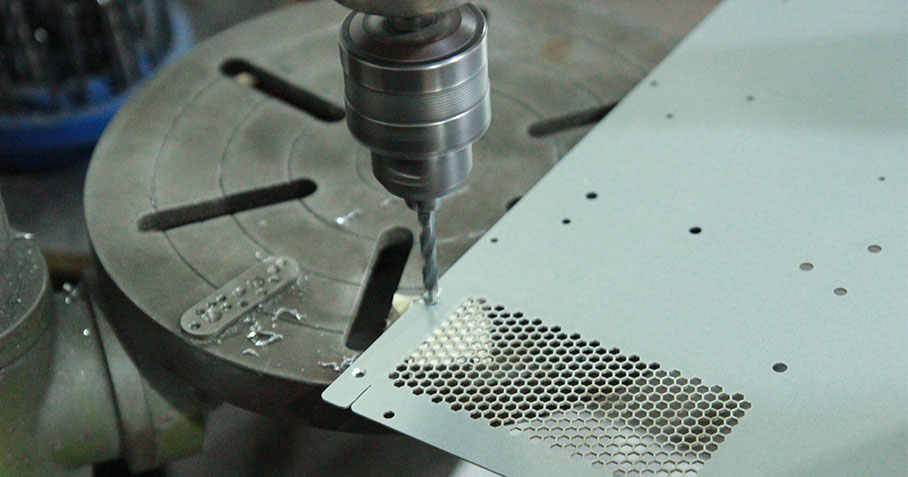

Metal pressing and forming include a variety of sheet metal stamping manufacturing processes, such as punching by using a sheet metal stamping press machine, blanking, embossing, bending, flanging and coining, etc. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part or could occur through a series of stages. The process is usually carried out on sheet metal. During the sheet metal pressings, through using highly specialized computer-aided drafting and manufacturing programs, sheet metal is transformed into complex parts. HSJ has the most professional sheet metal pressings technology which can ensure the high quality of our products.

| Items | Parameter |

| Part Material Selection | Parts can be formed, stamped, or fabricated Material options include Carbon Steel, Stainless Steel, Aluminum, or Copper Alloys The annual quantity per part number ranges from 1,000 units to 100,000 units. |

| Part Size |

We also offer customization for larger part sizes upon request. |

| Value Added Secondaries | Orbital Riveting CD Stud Welding PEM Fastener Insertion Kitting & Labeling Machining |

| Part Thickness | Hot Rolled Steel, Cold Rolled Steel, or Galvanized Steel: 0.15" to 0.194" (6 gauge) Annealed Stainless Steel: 0.015" to 0.120" Aluminum or Copper Alloys: 0.015" to 0.190" |

| Part Tolerances | Pierced Holes: +/- 0.003" on the shear side of the hole Blanked Dimensions: +/- 0.005" on the shear side of the part Formed Dimensions: +/- 0.010" inside of the bend Bend angles: +/- 1 degree |

| Part Information Desired for Quotes | Part drawings Part volumes Material and finish specifications Brief description of the project Samples (if available) |

Sheet metal pressings and dies can work with various metals to diverse parts in HSJ Fabrication's steel stamping factory. Metal pressing and forming material includes galvanized stamping parts like SGCC galvanized plate, SECC electrolytic plate, SUS stainless steel (model 201 304 316, etc.), SPCC iron plate, white copper, red copper, AL aluminum plate (model 5052 6061, etc.), SPTE, spring steel, manganese steel. Each metal pressing and forming material has its own advantages.

Automakers benefit from the sheet metal pressing for different parts. The dies can be used again to manufacture parts with the same size and shape. All parts are guaranteed to meet strict specifications and tolerances.

Key benefits of our metal pressing and forming include: High quality, Low Cost, long-term durability and Fast Turnaround Time.

In HSJ Metal Fabrication, metal pressing and forming can be handled almost entirely by machinery. Not only does this reduce the risk of human error or inconsistency, but it also lowers labor costs.

If you’re an automotive manufacturer looking for stamping sheet metal parts suppliers, choose HSJ Metal Fabrication.

Our state-of-the-art stamping equipment produces precision metal stamping parts quickly and easily, without sacrificing quality. HSJ Metal Fabrication as a reliable sheet metal stampings supplier, utilizes advanced production equipment to deliver metal stamping parts of high quality, high precision.

Our advanced stamping equipment and technology includes: Quick change tooling, Die conversions, Tool and die making equipment, Press equipment

We can do the custom sheet metal stamping of the chassis, fuel tank, radiator, boiler steam drum, container casing, motor, electrical iron core silicon steel sheet. Stamping parts for instruments, household appliances, bicycles, office machinery, living utensils, etc. Accuracy can reach 0.05mm, no stain on the surface, etc. For example, auto parts support.

Material: sus304

Surface: Deburring, no scratches.

Process: stamping

Accuracy: ±0.2

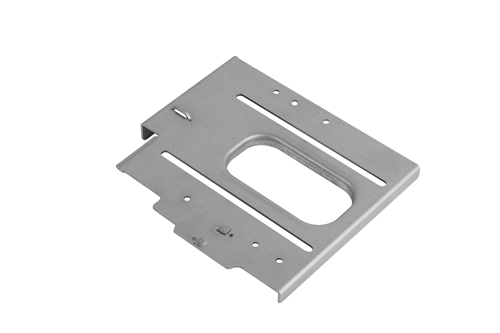

Material: Aluminum 6061-T6

Surface treatments Finish: Steel color

Process: Stamping

Tolerance: +/-0.01mm

We can also manufacture electronic parts box.

There are several types of metal pressing and forming techniques used in the manufacturing industry. Some of the most common types include:

Stamping: This involves using a press machine to create shapes and forms on a metal sheet.

Deep drawing: This is a type of stamping that involves creating a three-dimensional shape by drawing a flat sheet of metal into a die.

Bending: This involves using a press brake to bend a metal sheet into a desired shape.

Rolling: This involves passing a metal sheet through a set of rollers to form it into a cylindrical shape.

Extrusion: This involves forcing a metal through a die to create a specific shape.

Hydroforming: This involves using a pressurized fluid to shape a metal sheet into a desired form.

Spinning: This involves rotating a metal sheet on a lathe while pressing it against a form to create a symmetrical shape.

Each of these techniques has its own unique advantages and disadvantages, and they are chosen based on the specific requirements of the project at hand.

Sheet metal pressing, also known as fabrication metal sheet stamping or sheet steel pressing, is a metalworking process that involves using a press machine to transform a flat sheet of metal into a specific shape or form. The process typically involves placing the sheet metal between two dies, which are then pressed together using a high force to create the desired shape or form.

Customized sheet metal stamping can be used with a variety of metals, including steel, aluminum, copper, and others. The dies used in the process can be made from a variety of hard materials, such as carbide, to ensure precision and accuracy in creating the final shape of the stamped metal part.

Custom sheet metal stamping is a versatile process that can be used to create a wide range of metal parts with varying shapes and sizes, making it a popular choice in industries such as automotive, aerospace, and electronics. The ability to customize the process to meet the specific requirements of each project makes it an efficient and cost-effective solution for manufacturers looking for precise and accurate metal fabrication techniques.

Sheet metal pressing, also known as fabrication metal sheet stamping or sheet steel pressing, offers several advantages over other metal forming processes.

One of the major advantages is the ability to produce high-quality metal parts with tight tolerances and consistent quality. This makes customized sheet metal stamping an ideal choice for industries that require precision and accuracy, such as aerospace, automotive, and electronics.

Another advantage of sheet metal pressing is the versatility it offers in terms of the shapes and sizes of the final product. The dies used in the process can be easily customized to produce a wide range of shapes and sizes, making it a popular choice for manufacturers looking for cost-effective and efficient metal fabrication solutions.

Sheet metal pressing also allows for efficient and high-volume production, which can help to reduce manufacturing costs and improve productivity. With automated press machines, manufacturers can quickly produce large quantities of metal parts with minimal labor requirements.

Overall, the major advantages of sheet metal pressing and forming include high precision, versatility, and efficiency, making it a popular choice for a wide range of industries that require high-quality metal parts.

Sheet metal stamping dies are specialized tools used in the sheet metal stamping process. They are commonly developed using computer-aided design (CAD) software and analytical programs to create and prove-out highly accurate, unambiguous designs. They are typically made from hard materials such as steel, carbide, or other alloys and are used to form a flat sheet of metal into a specific shape or form.

The die consists of two parts, the male and female sections, that are designed to fit together precisely to create the desired shape of the stamped metal part. The male section, also known as the punch, is mounted on the press machine and moves downward to apply pressure to the metal sheet. The female section, also known as the die, is mounted on the press bed and supports the sheet metal as it is formed.

There are many different types of sheet metal stamping dies, including compound dies, progressive dies, and transfer dies, each of which is used to produce different types of metal parts. The type of die used depends on the complexity of the part and the desired production volume.

Sheet metal stamping dies are critical components in the sheet metal stamping process, and their design and manufacture require a high degree of precision and expertise.