Custom metal boxes play a crucial role in various industries, serving as durable, secure, and tailored storage solutions. But have you ever wondered about the intricate process behind bringing these custom metal boxes to life? In this blog, we'll take you through the journey from concept to creation and unveil how custom metal box manufacturers work their magic.

The journey begins with understanding the client's needs. Custom metal box manufacturers engage in detailed discussions with their clients to determine the exact specifications of the required metal box. This includes size, shape, purpose, design, material preferences, and any special features or requirements.

Once the client's requirements are clear, custom metal box manufacturers move on to the design phase. Skilled designers create detailed plans, including precise measurements and specifications. In some cases, 3D prototypes may be developed to visualize the final product accurately. This step ensures that the client's vision aligns with the proposed design.

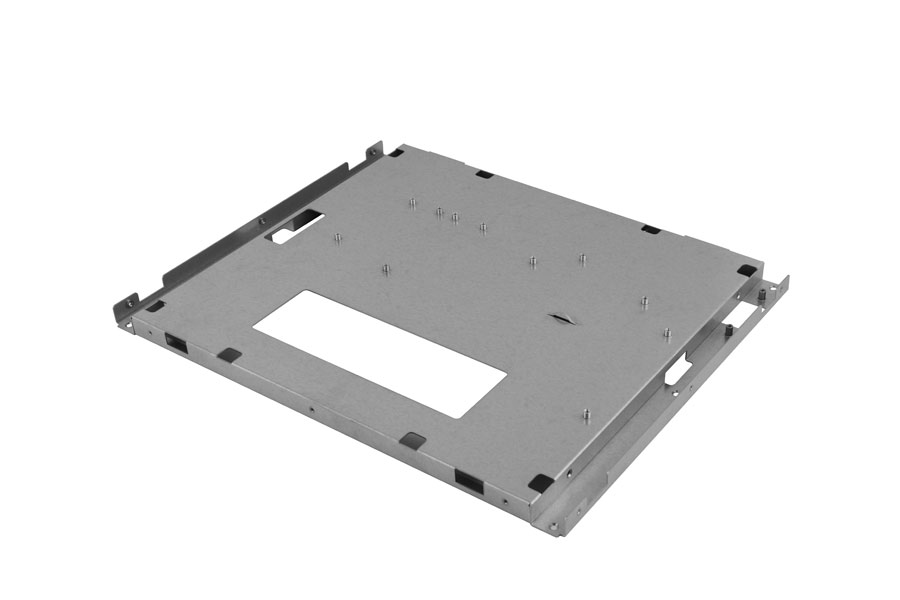

Metal box manufacturers carefully select the appropriate materials based on the project's needs and design specifications. Common materials include steel, aluminum, and stainless steel. The selected metal sheets are then cut, shaped, and fabricated according to the design, with an emphasis on precision and accuracy.

The next stage involves assembling the custom metal box. Skilled craftsmen weld, rivet, or fasten the various components together, creating the box's structure. This assembly phase ensures that the box is sturdy and meets the necessary strength and security requirements. After assembly, the metal box undergoes finishing processes, which may include surface treatments like painting, powder coating, or plating for added protection and aesthetics.

Quality control is a critical step in the process. The custom metal box undergoes rigorous inspection to ensure it meets all specified dimensions, design requirements, and industry standards. This meticulous quality control process guarantees that the final product is of the highest quality and ready to serve its intended purpose.

Custom metal box manufacturers play a pivotal role in bringing bespoke storage solutions to life. From the initial understanding of the client's needs to the design and prototyping phase, material selection, assembly, and finishing, the process is a carefully orchestrated journey that demands precision and expertise. Quality control and inspection ensure that the final product aligns with the client's vision and meets the highest industry standards.

Custom metal box manufacturers are masters of their craft, combining creativity with engineering, metalworking, and quality assurance to create a wide range of metal boxes, from toolboxes to enclosures, that cater to diverse industries and purposes. Their commitment to turning concepts into reality is what makes custom metal boxes reliable and indispensable assets in the business world.