An iron alloy containing 10.5% chromium and 0.2-2.11% nickel is called stainless steel, which produces an oxide passivation layer when exposed to air. This oxide layer can protect the internal materials from further oxidation. The passivation layer is the main reason why stainless steel has high corrosion resistance.

In common, stainless steel is a general term for stainless steel and acid resistant steel.

Stainless steel: Steel that does not rust in weakly corrosive media such as atmosphere and fresh water.

Acid resistant steel: Steel that is resistant to corrosion in harsh corrosive media such as acid, alkali, salt, and seawater.

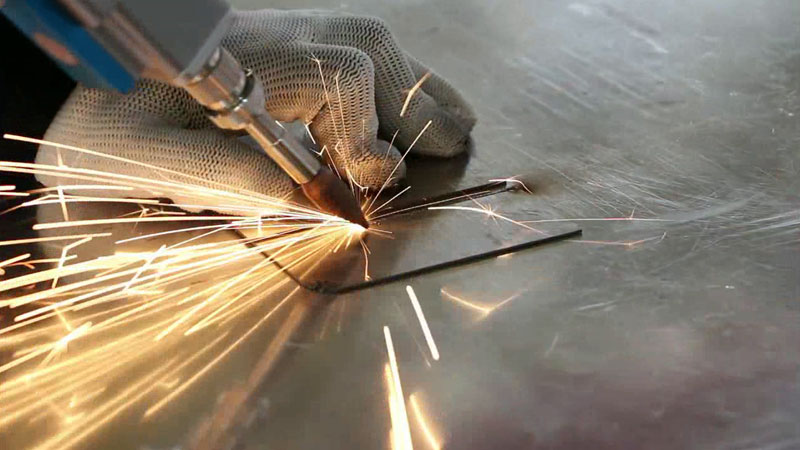

Weldability

The requirements for welding performance vary depending on the different uses of the product. A type of tableware generally does not require welding performance, and even includes some pot enterprises. But the vast majority of products require good welding performance of raw materials, such as second-class tableware, insulated cups, steel pipes, water heaters, water dispensers, etc.

Corrosion resistance

The vast majority of stainless steel products require good corrosion resistance, such as first - and second-class tableware, kitchenware, water heaters, water dispensers, etc. Some foreign merchants also conduct corrosion resistance tests on their products: heating NACL aqueous solution to boiling, pouring out the solution after a period of time, washing and drying, and weighing the weight loss to determine the degree of corrosion (note: when polishing the product, the presence of Fe in the sandpaper or sandpaper may cause rust spots on the surface during testing)

When the number of chromium atoms in steel is not less than 12.5%, it can cause a sudden change in the electrode potential of the steel, rising from negative potential to positive electrode potential. Prevent electrochemical corrosion.

Polishing performance

In today's society, stainless steel products are generally polished during production, with only a few products such as water heaters and water dispenser liners not requiring polishing. Therefore, this requires good polishing performance of the raw materials. The main factors affecting polishing performance are as follows:

① Surface defects on raw materials. Such as scratches, pitting, acid pickling, etc.

② Raw material material issues. If the hardness is too low, it is difficult to polish (poor BQ properties), and if the hardness is too low, the surface is prone to orange peel phenomenon during deep stretching, which affects BQ properties. BQ with high hardness has relatively good properties.

③ Products that have undergone deep stretching will also have small black spots and RIDGING on the surface of areas with significant deformation, which will affect their BQ properties.

Heat resistance performance

Heat resistance refers to the ability of stainless steel to maintain its excellent physical and mechanical properties at high temperatures.

The influence of carbon: Carbon is an element that strongly forms and stabilizes austenite in austenitic stainless steel, and expands the austenite region. The ability of carbon to form austenite is about 30 times that of nickel. Carbon is a interstitial element that can significantly improve the strength of austenitic stainless steel through solid solution strengthening. Carbon can also improve the stress and corrosion resistance of austenitic stainless steel in high concentration chloride solutions (such as 42% MgCl2 boiling solutions).

Although stainless steel has excellent corrosion resistance, it is not absolutely rust free. Stainless steel may still corrode even when the surface passivation film is damaged, the environment is highly corrosive, or the surface is contaminated. By selecting appropriate stainless steel grades, regular cleaning and maintenance, and avoiding mechanical damage, the service life of stainless steel can be effectively extended and rust prevention can be prevented

1. Grade

304L and 316L extend from 304 and 316, respectively, with the following grades:

304 is 06Cr19Ni10304L and 00Cr19Ni10;

316 is 0Cr17Ni12Mo2316L and 00Cr17Ni14Mo2.

2. The content of 304 and 316 materials is different.

3. Food grade

People often ask if 304 is food grade? In fact, when it comes to material, the content of 304 material has reached food grade. There are approximately three common food grade materials in the market: 304, 316, and 430 stainless steel. 304 is commonly used in small household appliances or water bottles, 316 is used in medical devices, and 430 is often made of stainless steel material for cutting tools. However, it is also necessary to clarify a concept here. It does not mean that the material is food grade, but also includes whether the manufacturing process meets food grade standards. For example, Xiyouwo specializes in decorative stainless steel pipes, while there are other stainless steel pipe factories that specialize in producing food grade stainless steel water pipes, and the required process steps are different.

4. Corrosion resistance

316 stainless steel is a stainless steel made by adding some molybdenum to 304 stainless steel for resistance to pitting corrosion. In various types of water quality (distilled water, drinking water, river water, boiler water, etc.), the corrosion resistance of 304 stainless steel and 316 stainless steel is almost the same, but when the content of chloride ions in the medium is very high, 316 stainless steel is more suitable.

5. Price

Due to the addition of molybdenum and nickel elements in 316, 316 stainless steel is more expensive than 304 stainless steel.

6. Low carbon

304L and 316L materials have lower carbon content compared to 304 and 316, and there is a clear comparison in the material content table. Stainless steel does not rust mainly due to the formation of a chromium rich oxide film on the surface, but intergranular corrosion occurs when the temperature is too high. Therefore, the low carbon content in 304L and 316L reduces intergranular corrosion. It should be noted that a higher sensitivity to intergranular corrosion does not necessarily mean that non low carbon content is more prone to corrosion, and this sensitivity is also higher in high chlorine environments.