Copper welding is a crucial joining process in metal manufacturing and processing. Copper and its alloys (such as brass and bronze) possess excellent electrical and thermal conductivity and corrosion resistance, making them widely used in industries such as electrical engineering, refrigeration, water supply and drainage, and machinery manufacturing. Achieving high-quality welded joints requires a thorough understanding of the fundamental principles, process characteristics, and key technical aspects of copper welding.

Copper has an extremely high thermal conductivity (approximately five times that of steel). Heat dissipates easily during soldering, making it difficult to maintain a sufficient melting temperature in the weld area. Furthermore, an oxide film easily forms on the copper surface, hindering solder wetting and bonding. Therefore, soldering copper requires:

Providing a high-power heat source.

Using an appropriate shielding gas or flux.

Selecting a low-melting-point solder to minimize heat input.

1. Oxy-Acetylene Welding

Gas welding is the most traditional copper welding method. Using an oxyacetylene flame as the heat source, it can weld thin copper sheets or non-structural components.

Advantages: Simple equipment and flexible operation.

Disadvantages: Large heat-affected zone, slow welding speed, and prone to oxidation.

2. TIG welding

TIG welding is a common method for welding copper and copper alloys. It uses an inert gas shield (argon or helium) to prevent weld oxidation.

Advantages:

Elegant weld bead

Suitable for thin plates and medium-thick copper parts.

Preheating (200–400°C) can be used to minimize heat loss.

For welding thick copper plates, double-sided welding or multi-layer overlay can be used.

3. MIG Welding (Metallic Inert Gas Welding)

MIG welding is suitable for thick copper parts and applications requiring high productivity. Its continuous wire feed significantly improves efficiency.

Advantages:

Deep penetration.

High welding speed.

Suitable for automated or mechanized production.

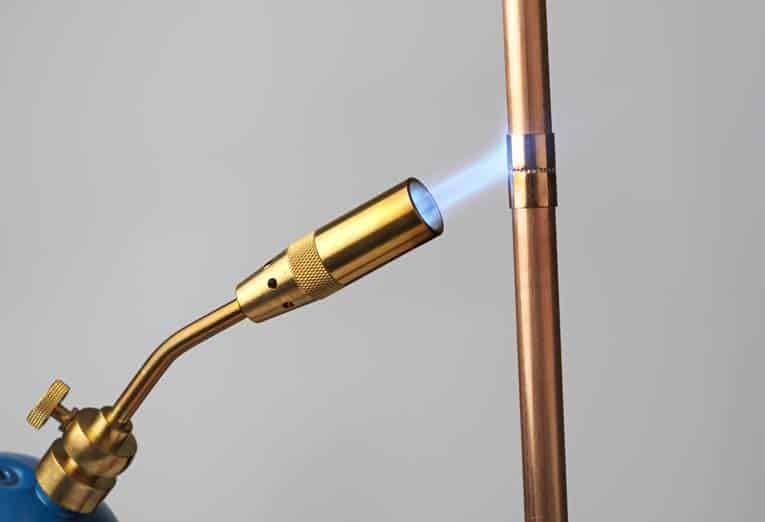

4. Silver Brazing and Phosphor Copper Brazing

Brazing is widely used for joining copper to copper and copper to steel. Silver-based brazing filler metals (such as Ag-Cu-Zn) and phosphor copper brazing filler metals are commonly used.

Advantages:

High joint strength.

Minimal thermal impact.

Especially suitable for thin-walled pipes and electrical components.

Does not alter the base material structure.

1. Surface Cleaning: Before welding, remove any oxide film and oil contamination. This can be done by mechanical grinding, chemical cleaning, or pickling.

2. Preheat Control: Control the preheat temperature based on plate thickness; for thick plates, it can reach 400°C to avoid partial penetration due to thermal diffusion.

3. Welding Current and Speed: Copper conducts heat quickly, so increase the welding current and reduce the welding speed to maintain the weld pool temperature.

4. Shielding Gas Purity: 99.99% pure argon or helium is recommended to avoid porosity and oxidation.

5. Post-weld Treatment: Perform slow cooling or annealing as necessary to eliminate residual stress and improve conductivity.

1. Lack of Fusion or Incomplete Welding

Due to copper's high thermal conductivity, insufficient heat input may result in insufficient melting of the weld metal. Ensure adequate fusion by preheating appropriately, increasing the welding current, and slowing the welding speed.

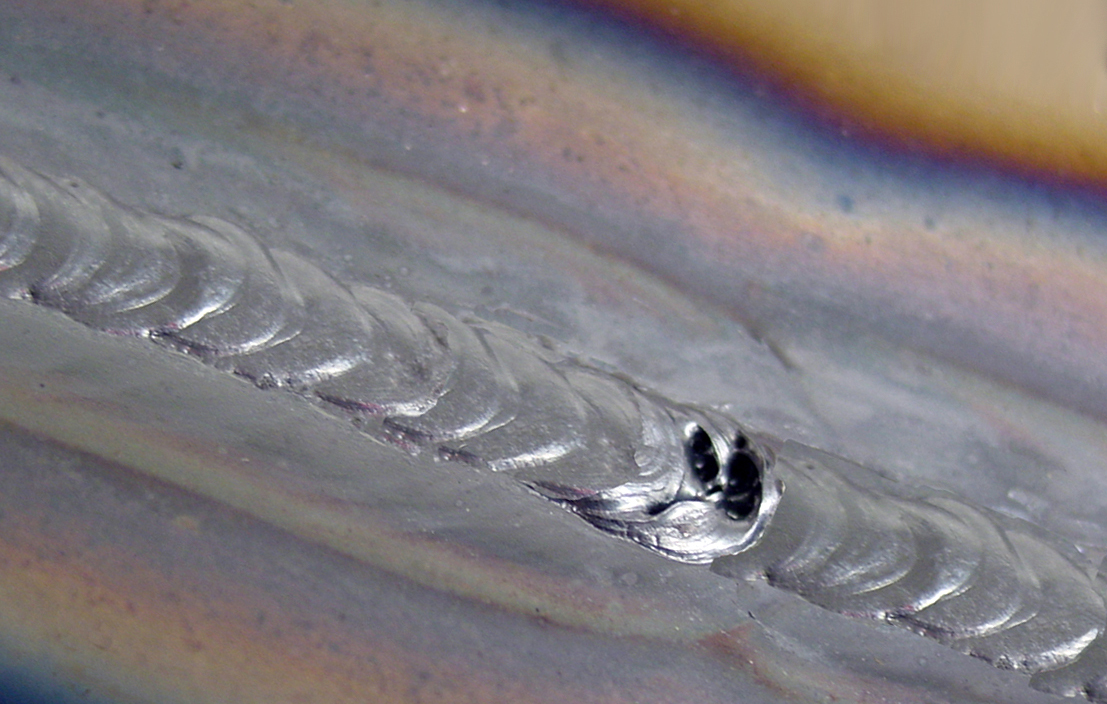

2. Porosity

Porosity is often caused by surface contamination or impure shielding gas. Before welding, thoroughly clean the workpiece to ensure the weld area is free of oil, dirt, or oxide film, and maintain stable gas purity and flow.

3. Cracks

Cracks are generally caused by excessive cooling or stress concentration. Preheating, controlling the cooling rate, and optimizing groove design can reduce internal stress and prevent cracking.

4. Welding Distortion

Excessive heat input or an improper welding sequence can cause thermal deformation in copper parts. Use segmented welding, symmetrical welding, or fixtures to control welding distortion.