Physical Vapor Deposition (PVD) technology refers to the process of using physical methods under vacuum conditions to vaporize the surface of a material source (solid or liquid) into gaseous atoms or molecules, or partially ionize into ions, and deposit a thin film with a certain special function on the substrate surface through low-pressure gas (or plasma) processes. PVD is one of the main surface treatment technologies.

PVD (Physical Vapor Deposition) coating technology is mainly divided into three categories: vacuum evaporation coating, vacuum sputtering coating, and vacuum ion coating. The main methods of physical vapor deposition include vacuum evaporation, sputtering coating, arc plasma coating, ion coating, and molecular beam epitaxy. The corresponding vacuum coating equipment includes vacuum evaporation coating machine, vacuum sputtering coating machine, and vacuum ion coating machine.

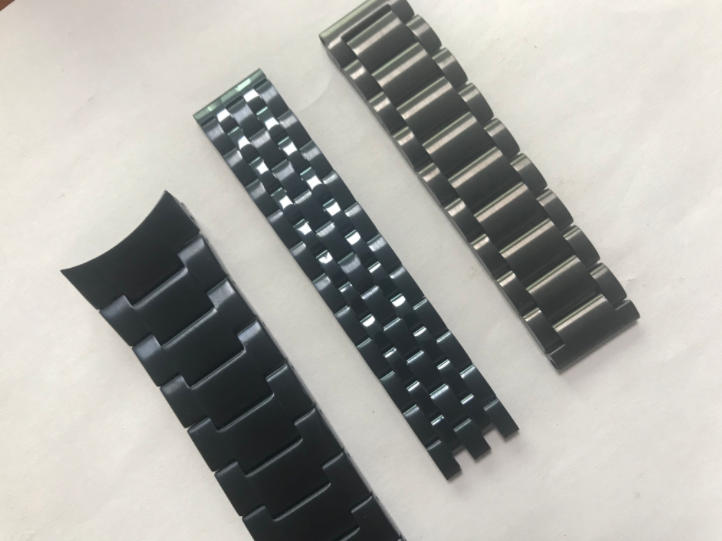

With the improvement of sedimentation methods and technologies, physical vapor deposition technology can not only deposit metal films, alloy films, but also compounds, ceramics, semiconductors, polymer films, etc.

The basic principle of physical vapor deposition technology can be divided into three process steps:

(1) Gasification of plating material: Even if the plating material evaporates, sublimates, or is sputtered, it is achieved through the gasification source of the plating material.

(2) Migration of atoms, molecules, or ions in the plating material: After collision, various reactions are generated by atoms, molecules, or ions supplied by a gasification source.

(3) Plating atoms, molecules, or ions deposit on the substrate.

Vacuum deposition

Vacuum evaporation coating, also known as vacuum evaporation coating, is the most common and widely used method in thin film preparation. Its principle is to use external heat to liquefy the film material (thin film material) under vacuum environment, or directly vaporize it into a gas state, and deposit it on the substrate to form a thin film technology. According to the source of heat, it can be divided into resistance evaporation plating, electron beam (EB) - coating, pulsed laser deposition (PLD), induction heating evaporation plating, etc.

Sputtering

It is a coating technology that generates ions (Ar) through gas discharge under vacuum conditions, and uses positively charged fluoride ions to bombard a solid target material with a negative potential, causing target atoms to sputter out and deposit onto the substrate surface to form a thin film. Vacuum sputtering plating can be divided into different sputtering devices, such as bipolar, triode or quadrupole sputtering, DC or RF line sputtering, magnetron sputtering, reactive sputtering, ion beam sputtering, etc. Among them, magnetron sputtering coatings are widely used, including DC planar magnetron sputtering coatings, columnar target magnetron sputtering coatings, non-equilibrium magnetron sputtering coatings, pulsed DC magnetron sputtering coatings, RF magnetron sputtering coatings, and intermediate frequency magnetron sputtering coatings.

Ion plating

Ion plating is one of the fastest developing and most widely used coating technologies. Film materials (thin film materials) change from solid to gas in a manner similar to evaporation plating or sputtering plating. However, gaseous film materials participate in glow discharge together with the working gas during subsequent transport, and some are ionized into ions and electrons. Ions and neutral particles deposit onto a substrate with a negative potential to form a thin film. Ion plating can be basically divided into three categories: plasma ion plating, arc vapor deposition, and beam ion deposition. The most typical characteristics that distinguish ion plating from evaporation plating and sputtering plating are:

① In ion plating, the vaporized membrane atoms undergo an ionization process.

② In ion plating, the substrate is usually subjected to a negative bias voltage. Coatings that meet these two conditions can basically be classified as ion plating.

PVD stands for Physical Vapor Deposition, a process used to coat materials with coatings. Some common metals that can be coated with PVD include titanium, stainless steel, and tungsten. These metals are typically chosen for PVD coatings because they are sturdy and durable. The use of PVD coated coatings can enhance their performance and extend their service life.

① Titanium

Titanium is a commonly used metal for PVD coatings because it is lightweight and corrosion-resistant. It is typically used in applications where strength and durability are crucial, such as the aerospace and medical industries. PVD coatings applied to titanium metal help protect it from wear and improve its appearance.

② Stainless Steel

Stainless steel is another common metal that can be coated with PVD. This type of steel is known for its corrosion resistance and dye resistance. PVD coatings can further enhance their performance in these fields. Stainless steel is commonly used in applications where cleanliness and hygiene are crucial, such as the food and beverage industry. PVD coating applied to stainless steel helps improve its resistance to staining and corrosion, and makes it look better.

③ Tungsten

Tungsten is a metal known for its high melting point and high-temperature strength. It is typically used for applications that must withstand extreme heat, such as the production of light bulbs and other types of lighting. PVD coating can help protect tungsten from corrosion and wear in these applications, and enhance its aesthetics..

Lower process temperature: The working temperature of PVD coating is about 500 ° C, which can minimize the risk of thermal damage to the substrate. This is particularly advantageous for materials sensitive to high temperatures, such as high-speed steel (HSS) and hard alloy cutting tools.

Precision and thin film: This process can accurately deposit thin films with an average coating thickness between 0.02 and 5 microns. This precision is crucial for applications such as optical coating and precision punching tools.

High hardness and wear resistance: PVD coatings can form ceramic and composite coatings with super hardness and wear resistance, making them suitable for demanding applications such as cutting tools and molds.

Compressive stress formation: During the cooling process, PVD coatings generate compressive stress, which helps prevent the formation and propagation of cracks. This makes them an ideal choice for intermittent cutting processes such as milling.

Aesthetic versatility: PVD coatings can replicate the appearance of expensive metals such as copper, brass, and gold, making them popular in the jewelry and watchmaking industries. With simple cleaning, the coating can maintain its original color.

Higher costs: Complex computer-controlled machines and skilled operators are required, which increases the overall cost of PVD coatings. This is a barrier for smaller or budget limited businesses.

Slow operating speed: Compared with other coating methods, PVD coating has a relatively slow processing speed, which may affect production time, especially in large-scale production.