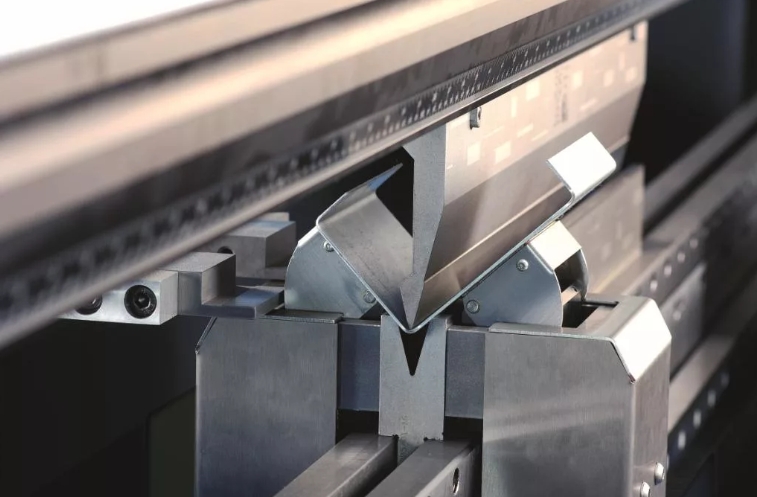

Bending is a type of deformation and one of the three main processes in sheet metal fabrication. The bending process uses a fixture or die to hold the metal part in position while applying force strategically to a specific area. The applied force must exceed the material’s yield strength to cause plastic deformation. This process forms V-, U-, or channel-shaped bends along an axis, creating new part geometries. Bending changes the shape of the sheet but not its volume.

The diversity of part shapes and applications in manufacturing has led to the development of numerous bend types. The use of each bend type depends on the part's intended use, the required geometry, and the material properties.

Single Bend

The simplest and most commonly used type. It allows sheet metal to be bent at a specified angle (usually 90°, 45°, or 120°). It is used to produce boxes, corner pieces, shelves, and other simple shapes.

Multiple Bend (Continuous)

This consists of a series of bends made at different locations on a single sheet of sheet metal. It is used to produce complex spatial components such as cabinets, panels, and mounting boxes.

Z-Bend

Consists of two offset, opposite bends. It is used to produce fasteners, rails, mounting brackets, and curtain wall substructures. It requires high precision to maintain dimensional and surface parallelism.

Radius Bend

This bend is made at a specific radius rather than a sharp angle. It is used for decorative items, enclosures, and design elements. It helps reduce metal stress and prevent cracking. Corner bends with flanges are most commonly used to create rigid frames, profiles, and components with additional ribs to increase structural strength.

1. Material and Thickness

Maintain consistent material thickness. Select metals with good ductility (such as aluminum or mild steel). Consider the material's yield strength and bending properties during design.

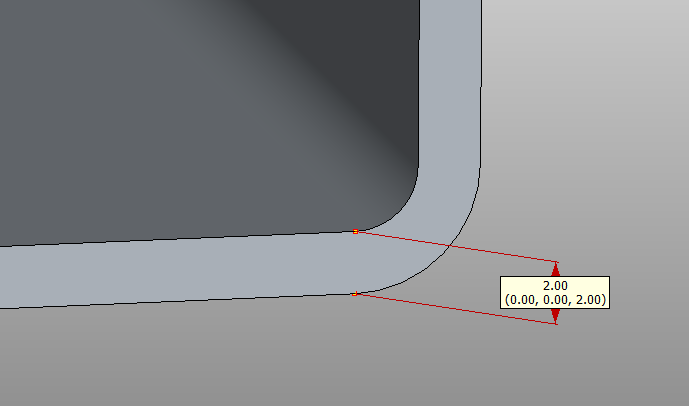

2. Bending Radius

The inner bend radius should be greater than or equal to the material thickness (R ≥ t) to prevent cracking. The bending direction should be perpendicular to the rolling direction as much as possible to reduce the risk of breakage.

3. Hole and Slot Spacing

The hole distance from the bending edge should be ≥ 2.5 to 4 times the sheet metal thickness; the slot distance from the edge should be ≥ 2 times the sheet metal thickness to avoid deformation or bulging during forming.

4. Springback and Unfolding

Different metals have different springback rates. The unfolding diagram must be accurately calculated based on the bend angle and K factor to ensure the assembly dimensions.

5. Reinforcement Structures and Riveted Fittings

The flange radius should be ≥ 2 times the sheet metal thickness. Riveted fittings should be ≥ 3 times the sheet metal thickness away from the bend line to avoid bending interference and localized stress concentration.

6. Relief Grooves and Assembly Space

Designing relief grooves (width ≥ thickness) at the bend prevents tearing and provides assembly space to ensure that parts do not interfere with each other.

Almost all common sheet metals can be bent, but the properties of the specific material greatly influence the choice of bending radius, bending force, and application technique. The following are the main materials commonly used in bending processes:

Steel (carbon steel and galvanized steel)

Bends well, especially when heated.

Suitable for construction and industrial needs.

Pre-treatment of the edges may be necessary to avoid cracking.

Stainless steel

It can be bent, but due to its hardness, greater force is required.

Accurately bending sharp corners without first calculating the minimum radius is not recommended.

Commonly used in the food, medical, and construction industries.

Aluminum and its alloys

Lightweight and flexible materials that bend easily.

However, excessive bending can cause cracks, especially in high-strength alloys, requiring careful equipment setup.

Copper and brass

They bend easily without heating, making them ideal for decorative and plumbing applications.

They are highly malleable.

Titanium

Strong, but difficult to bend.

Precise calculations and specialized equipment are required.

Sheet thickness

Yield strength

Presence of coatings (for example, zinc or powder coatings may crack when bent)

At HSJ, We provide high-precision, fast, and high-quality sheet metal bending and fabrication services for parts made from sheet metal such as aluminum, steel, and copper alloys. Using automated bending technology, we guarantee high precision and ready-made part quality. We can also provide finish according to your requirements.