Rolling metal refers to the process of reducing the thickness, increasing the length, or changing the cross-sectional shape of a metal material by rolling it between one or more pairs of rotating rollers. Rolling is a form of pressure forming. Its core principle is to plastically deform the metal under the intense pressure of rollers at either high or room temperature, thereby obtaining plates, strips, bars, or profiles with the desired dimensions and properties.

The goals of rolling are not only to reduce metal thickness but also to:

Improve the metal's mechanical properties (such as increasing strength and toughness).

Produce a more uniform microstructure.

Produce the desired surface quality and shape accuracy.

Hot rolling is a rolling process performed above the metal's recrystallization temperature. At high temperatures, the material exhibits excellent plasticity, making it easier to form.

Features:

Significantly reduces forming resistance.

The finished product has a dense microstructure but a rough surface.

Some degree of scale and dimensional deviation may occur.

Common Products:

Hot-rolled steel plates and strips.

Steel sections (such as H-beams, I-beams, and angles).

Hot-rolled steel bars and rails.

Typical Applications:

Bridges and building structures.

Automobile chassis and machinery frames.

Thick plate weldments, etc.

Cold rolling is performed below the metal's recrystallization temperature. At this point, the metal is significantly hardened, requiring multiple rolling passes and intermediate annealing to restore plasticity.

Features:

High dimensional accuracy.

Excellent surface finish.

Increased strength but reduced plasticity.

High production cost.

Common Products:

Cold-rolled sheet (SPCC, DC01, etc.).

Stainless steel strip.

Copper and aluminum foil.

Typical Applications:

Appliance housings, automobile bodies.

Precision stampings.

Electronic components and decorative parts.

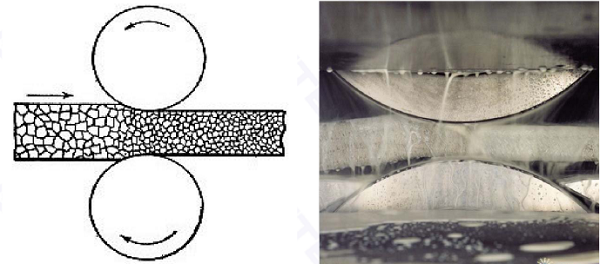

Longitudinal Rolling: Rolling is performed along the length of the metal, the most common method.

Cross Rolling: The metal is rotated at an angle to the rolling direction, often used for forming spheres and rings.

Helical Rolling: An important process for manufacturing seamless steel pipes.

Foil Rolling: Used for extremely thin materials such as aluminum and copper foil.

High production efficiency: Continuous and highly automated.

Excellent dimensional consistency: Thickness tolerance can be controlled to within micrometers.

Dense metal structure: Reduces defects and improves mechanical properties.

Wide application: Almost all metal materials can be rolled.

Manageable costs: High raw material utilization compared to forging or casting.

Rolled metals permeate nearly every industrial manufacturing sector. In the construction and structural industries, hot-rolled steel plates, I-beams, and channels are widely used in load-bearing structures such as bridges, factory buildings, and high-rise buildings.

In the automotive industry, cold-rolled steel plates, with their excellent surface quality and high strength, are a key material for body panels and chassis.

Home appliance manufacturing relies on cold-rolled plates for housings, backplanes, and internal brackets.

The aerospace industry frequently uses high-strength aluminum plates and titanium strips that have been cold-rolled and heat-treated for aircraft skins and structural components.

The electronics industry makes extensive use of cold-rolled copper strip and aluminum foil for circuits, connectors, and heat sinks.

In the energy equipment sector, hot-rolled thick plates are used to manufacture key components such as pressure vessels, oil and gas pipelines, and wind turbine towers.