In the sheet metal manufacturing industry, copper and copper alloy products are widely used in electronics, communications, architectural decoration, and precision parts due to their excellent electrical conductivity, thermal conductivity, and corrosion resistance.

Excellent electrical and thermal conductivity: Copper's electrical conductivity is second only to silver, making it an irreplaceable material in the electronics and electrical engineering industries.

Excellent formability: Copper has excellent ductility and plasticity, allowing it to be formed through a variety of sheet metal processes, such as bending, stamping, and stretching.

Corrosion resistance and durability: Copper naturally forms an oxide film on its surface when exposed to air, effectively preventing further corrosion.

Beautiful appearance: Copper and its alloys have a unique metallic luster. Polishing, electroplating, brushing, and other processes create both aesthetics and practicality.

Environmentally friendly and recyclable: Copper is a recyclable metal, aligning with the concept of sustainable development.

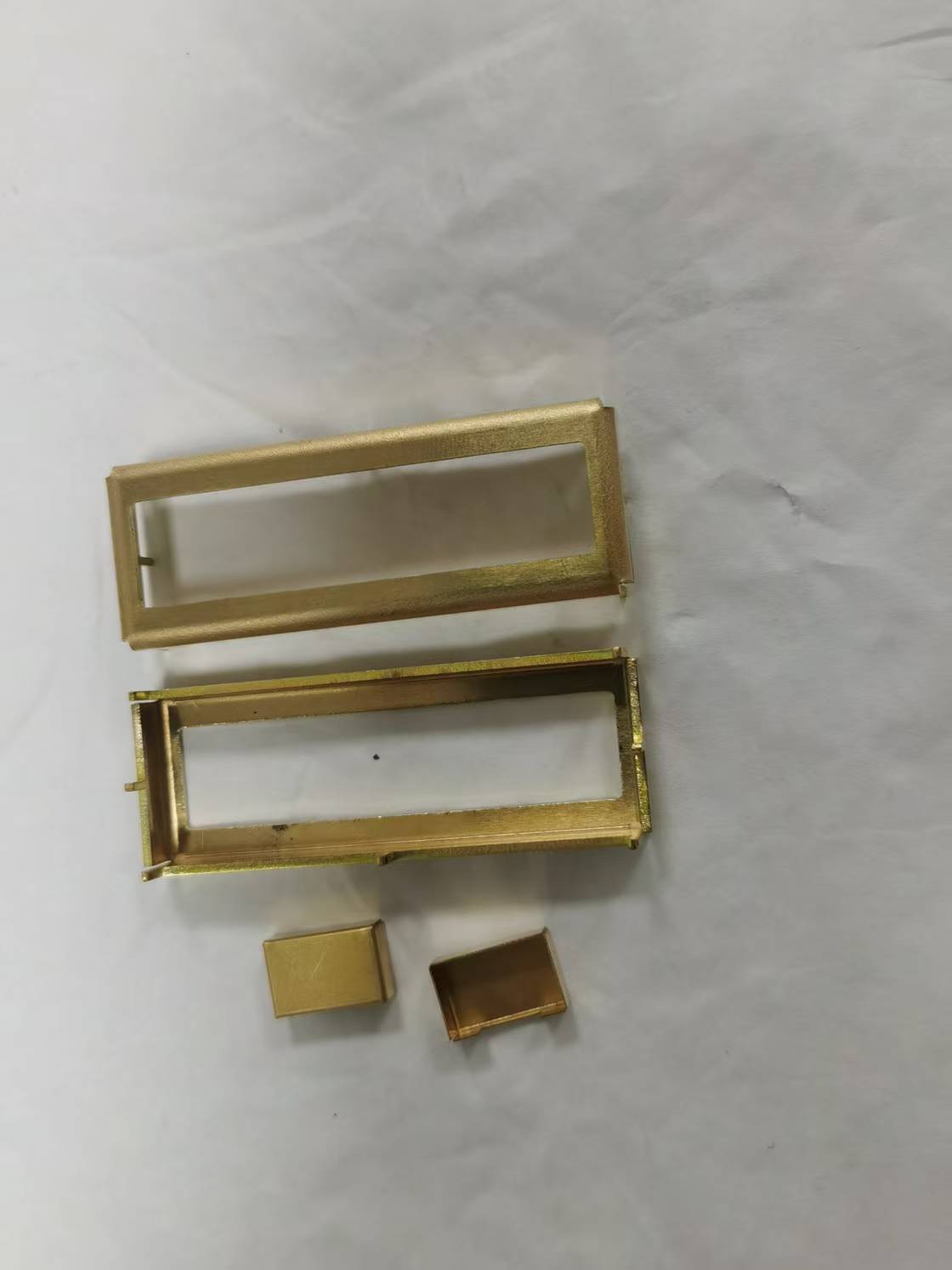

This rectangular copper housing consists of a frame and a small cover. It is formed by bending and splicing, with some small parts welded to the frame.

Surface Finish: Gold-colored, spray-coated or electroplated.

Applications: Suitable for shielding and protection of electronic equipment, ensuring electromagnetic interference shielding performance while also providing excellent mechanical strength and aesthetics.

Rust generally refers to the reddish-brown formation of iron oxide when iron reacts with oxygen and moisture. The corrosion products of copper are primarily copper oxide or copper carbonate, which are often dark brown or green in color. This layer is called verdigris (patina).

Indoors, the surface of copper gradually darkens, forming a brownish-brown oxide film. In humid environments or those containing sulfur dioxide or carbon dioxide, copper gradually develops a green verdigris.

Unlike iron rust, verdigris is typically denser and, to a certain extent, protects the metal underneath from further corrosion.

Surface coating protection

Electroplating: Common methods include nickel plating, chrome plating, and gold plating, which both prevent oxidation and enhance appearance.

Spraying/powder coating: Creates a protective film on the copper surface, isolating it from air and moisture.

Clear varnish: Used for decorative copper pieces to preserve the original metallic texture.

Regular maintenance

Copper pieces can be cleaned regularly with a specialized copper polish to remove the surface oxide layer.

Maintain a dry environment and avoid prolonged contact with moisture, acids, or bases.

Material selection

Copper alloys (such as brass and bronze) generally offer better corrosion resistance than pure copper.

Electronics and the electrical industry

Shielding covers, connector housings

Electrical connectors, heat sinks

Communications and precision equipment

High-frequency electronic components

Precision instrument housings

Architecture and decoration

Copper doors, copper decorative parts

Architectural curtain walls, art sculptures

Home appliances and daily necessities

High-end kitchenware and bathroom accessories

High-end home appliance housings

As one of the professional China sheet metal fabrication manufacturers, HSJ takes pride in producing high-quality fabricated parts with superior strength, durability, and excellent processing performance. Our expertise ensures that every component meets strict industry standards while offering cost-effective and customized solutions.