Sheet metal processing bending is an indispensable part of the sheet metal manufacturing process, which involves bending flat metal sheets into the desired shape to produce various metal products.

Sheet metal bending is the use of mechanical or manual methods to apply external force, causing plastic deformation of metal sheets at the bending line, thereby forming specific angles and shapes. During the bending process, the outer side of the metal sheet is subjected to tensile force, while the inner side is subjected to compressive force. The inner radius of the bent part is smaller, while the outer radius is larger.

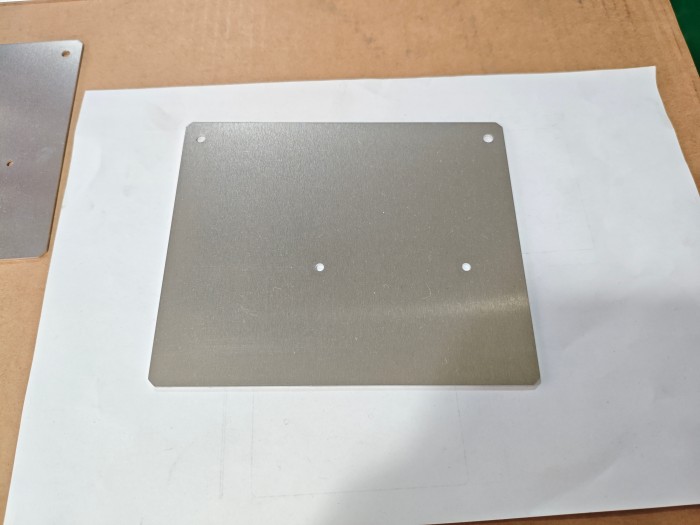

Part of the bent products:

Bending machine

The bending machine in the picture is one of the commonly used bending machines.

CNC system: The touch screen on the right can input precise bending angle, pressure, and stroke parameters, ensuring that every bending is precise and accurate.

Multi station mold: The red locking mold on the body can be quickly replaced and adapted to metal plates of different shapes and thicknesses, easily handling everything from simple right angles to complex contours.

Safety design: The equipment is equipped with protective devices and emergency stop functions, in accordance with operating standards, to ensure the safety of personnel and equipment.

A flat metal sheet needs to go through the following key steps to become a qualified bent part:

1. Preliminary preparation

Drawing analysis: Technicians will determine the bending sequence, angle, and mold selection based on the drawings and process documents provided by the customer.

Plate positioning: Before operation, the bending operator will accurately place the metal plate that has been laser cut and punched on the workbench of the bending machine, ensuring that the reference edge is aligned with the mold.

2. Precise bending operation

Mold adaptation: Select the appropriate upper and lower molds based on the bending angle, and quickly fix them with a red lock buckle.

Numerical control input: Enter bending parameters on the touch screen, and the equipment automatically calculates pressure and stroke.

Human machine collaboration: Workers wear anti slip gloves to assist in the positioning of the board, ensuring that the board does not shift during the bending process.

Start bending: After the equipment is started, the upper mold is pressed down, and the metal sheet undergoes plastic deformation between the molds to form the desired angle. Complex components will undergo multiple positioning tests and bending, gradually forming.

3. Quality inspection and closure

Size inspection: After the bending is completed, workers will use tools such as protractors and calipers to inspect the angle and size to ensure compliance with the drawing requirements.

Surface protection: To avoid scratches on the finished product, it is usually wrapped in white paper or pearl cotton, neatly stacked on cardboard, and waiting for the next step of assembly or shipment.

.png)

Sheet metal bending is an important processing technology in the manufacturing industry. By selecting appropriate equipment and materials, setting reasonable process parameters, and improving operational skills, the bending quality can be significantly improved to meet various complex shapes and high-precision manufacturing needs.