In the ever-evolving landscape of industrial machinery, the quest for efficiency, functionality, and safety has led to the integration of innovative materials and designs. One such transformative element making its mark is the use of perforated sheet metal panels in machinery enclosures. This blog delves into the industrial evolution brought about by the incorporation of perforated sheet metal panels, highlighting their impact on machinery enclosures.

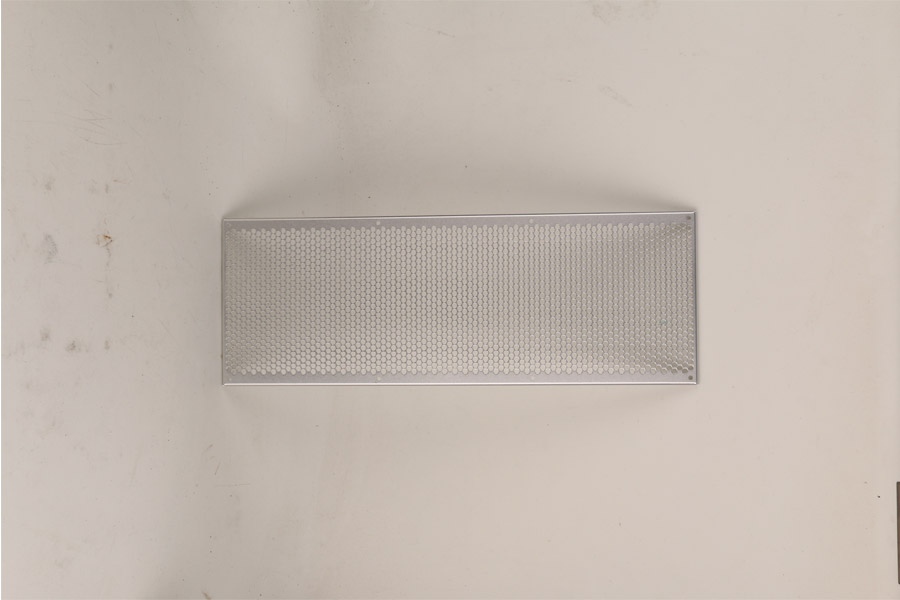

Machinery enclosures often house complex equipment generating significant heat during operation. Perforated sheet metal panels play a crucial role in improving ventilation and cooling efficiency within these enclosures. The precision-engineered perforations allow for the passage of air, preventing the buildup of heat and ensuring optimal operating conditions for machinery. This enhanced cooling capability contributes to the longevity and performance of industrial equipment.

Industrial settings are notorious for their noise levels, with machinery often being a significant contributor. Perforated sheet metal panels offer a solution to this challenge by acting as effective sound absorbers. When strategically applied in machinery enclosures, these panels help reduce noise levels, creating a quieter and more conducive working environment. This not only enhances worker comfort but also addresses regulatory requirements for noise control in industrial facilities.

The versatility of perforated sheet metal panels allows for customization to meet the specific requirements of different machinery. Whether it's optimizing airflow, integrating cable management solutions, or accommodating control panels, these panels can be tailored to the unique needs of diverse industrial equipment. This adaptability ensures that machinery enclosures are not only functional but also seamlessly aligned with the intricacies of the machinery they house.

Industrial machinery faces various challenges, including exposure to harsh environments, dust, and debris. Perforated sheet metal panels act as a durable protective shield for sensitive components within machinery enclosures. The robust construction of these panels provides a barrier against external elements, extending the lifespan of machinery and minimizing the risk of damage. This durability is particularly crucial in industries where equipment reliability is paramount.

Beyond functionality, perforated sheet metal panels contribute to the aesthetic evolution of industrial machinery enclosures. The modern design possibilities offered by these panels allow for the creation of sleek, visually appealing enclosures that align with contemporary industrial design trends. This not only enhances the overall look of machinery but also reflects a commitment to innovation and cutting-edge technology.

In conclusion, the industrial evolution facilitated by perforated sheet metal panels in machinery enclosures signifies a paradigm shift towards efficiency, safety, and design innovation. From improving ventilation and reducing noise to customization for specific machinery requirements, the impact of these panels goes beyond the surface, influencing the core functionality and longevity of industrial equipment. As industries continue to evolve, perforated sheet metal panels stand as a testament to the transformative power of materials in shaping the future of industrial machinery.