In modern industrial manufacturing, sheet metal box fabrication, as a key production link, is widely used in products such as chassis cabinets, control cabinets, and power equipment enclosures. It encompasses the entire process from drawing design, material cutting, forming, welding to surface treatment, and final assembly. To ensure the precision and durability of the products, choosing an experienced sheet metal box supplier is particularly important.

The first step in sheet metal processing starts with the design drawing stage. Technicians draw structural and unfolded drawings based on customer requirements, providing standards for subsequent processing steps. Especially in sheet metal box manufacturing, reasonable structural design directly affects the assembly accuracy and functionality in the later stages.

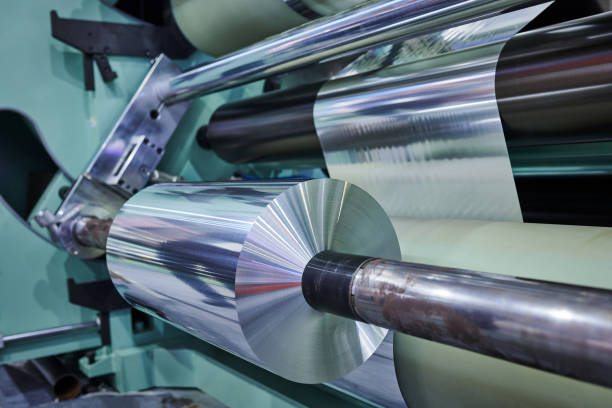

Laser cutting is currently one of the most widely used sheet cutting technologies, especially suitable for sheet metal box manufacturing projects that require high precision. The high-energy laser beam can accurately cut sheets of 1.5mm and thicker, with smooth and burr-free edges, greatly improving processing efficiency and saving mold costs.

For processing holes with regular shapes, the CNC turret punch press, with its fast, precise, and programmable advantages, holds an irreplaceable position in large-scale sheet metal box manufacturing. By changing the mold, it can efficiently complete the processing of complex hole shapes such as round holes, square holes, and long holes.

Bending is a highly technical process in the entire sheet metal box manufacturing process, requiring operators to fully understand the ductility and springback characteristics of different metals. Reasonable bending sequences and angle control are the keys to ensuring product size and structural accuracy.

The bent sheet metal parts need to be spliced and formed through welding methods. Depending on the product structure and strength requirements, different welding methods such as argon arc welding and MIG welding can be used. High-quality welding can ensure the overall strength and sealing of the sheet metal box after manufacturing.

After welding, the process enters the surface treatment stage, commonly using electrostatic powder coating. This process not only makes the product surface dustproof and waterproof but also provides good corrosion resistance and weather resistance. For most sheet metal box manufacturing projects, powder coating is the default and recommended process.

Some customized projects require printing logos or labels on the chassis. In this case, UV flatbed printing becomes the mainstream choice as it forms shapes in one go with clear patterns and is environmentally friendly without odors. It is more suitable for batch diversified sheet metal box manufacturing needs compared to traditional screen printing.

In products requiring sealing or dustproof and waterproof capabilities, CNC gluing has replaced manual strip application as a trend. It makes the adhesive strips more firmly bonded and the surface smoother, which is an effective means to improve the quality of sheet metal box manufacturing.

After all the components are made, they enter the assembly stage. Experienced assemblers accurately connect each component to form the final product. For customers who value efficiency and quality, choosing a sheet metal box supplier can ensure the product is delivered in an integrated manner from processing to assembly, saving time and effort.

From raw materials to finished products, every step determines the quality of sheet metal products. HSJ, as an important sheet metal box supplier, not only provides comprehensive processing services but also offers technical support and quality assurance at every stage of sheet metal box manufacturing. As the manufacturing industry moves towards intelligent and customized development, professional sheet metal processing capabilities will become one of the core competencies of enterprises.