The quality of a product depends not only on the precision of the machine tool and the level of craftsmanship, but also on the storage method of the parts while waiting for processing. Whether it is raw materials to be processed, work in progress waiting for the next process, or finished products that have just been produced, scientific storage methods are the key to avoiding deformation, scratches, and rust.

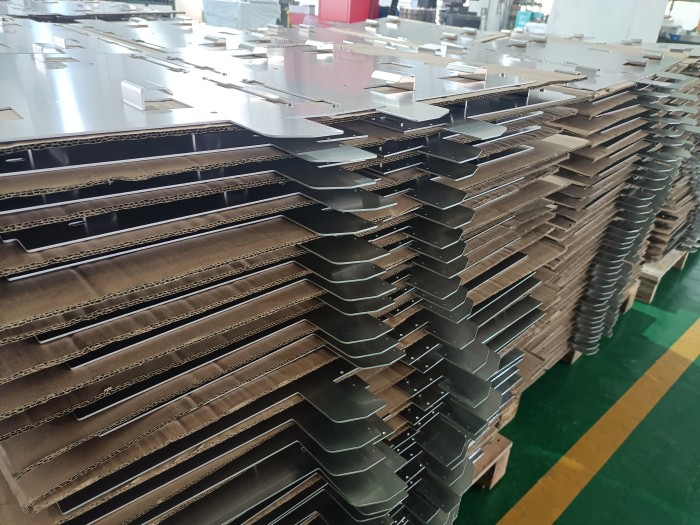

In the HSJ factory, all newly cut and bent metal parts follow a clear set of storage standards:

Layered protection: Inserting cardboard or corrugated paper between metal parts can isolate direct contact between metal surfaces, prevent sharp edges from scratching the board, and also avoid deformation caused by pressure during stacking.

Cardboard bearing: All work in progress products are placed on wooden cardboards to avoid moisture and wear caused by direct contact with the ground, while also facilitating forklift transportation and reducing the risk of manual handling collisions.

Pending processing area identification: The yellow markings on the ground have been divided into dedicated "pending processing areas". Work in progress products from different processes will be neatly stacked in batches, with process numbers and estimated processing times marked to ensure that production flow is not chaotic.

Load bearing matching: For metal plates with precision holes, we will choose heavy-duty pallets with stronger load-bearing capacity and strictly control the stacking height to prevent collapse or deformation of the plate due to a high center of gravity.

Dry and ventilated: The processing area should be located in a well ventilated area of the workshop, away from water sources and steam equipment. For metal parts with anti rust coating on the surface, we will install cardboard and divide them with cardboard, then wrap and cover them with plastic film to maintain stability and prevent dust and moisture from adhering.

Finished product: Temporary storage specifications after processing completion

After all the processing steps of the metal parts are completed, they enter the "finished product waiting area", and we also have strict storage standards to ensure safety:

1. Classified storage, upgraded protection

.jpg)

Independent packaging: for finished products with precise interfaces, we will first wrap the corners with foam cotton, and then seal the box with wrapping film to avoid secondary damage before transportation.

Cardboard fixation: The finished boxes will be uniformly stacked on the cardboards and secured with wrapping film in a "cross cross" pattern to prevent slipping during stacking. At the same time, a certain gap between the cardboards will be reserved for easy passage by forklifts and personnel.

2. Separate the inspection area from the qualified product area

Inspection Area Identification: Newly produced products will be placed in the "Inspection Area" and labeled with a yellow inspection tag. After passing the inspection by quality inspectors, they will be transferred to the "Qualified Product Storage Area".

From the layered isolation of work in progress to the classification and protection of finished products, these seemingly trivial storage details are precisely an extension of our understanding of the word 'quality'. On the track of custom metal processing, we not only pursue "precision processing", but also care about "safety throughout the entire process" - after all, only by keeping every product intact from production to delivery can we truly win the trust of customers.