In the intricate world of electronic manufacturing, precision is not just a goal—it's a necessity. As technology continues to advance, the demand for smaller, more complex electronic components grows, and so does the need for manufacturing processes that can deliver on these exacting requirements. Enter precision metal stamping, a transformative technique that goes beyond traditional molds and dies, shaping the future of electronic parts production.

The Basics

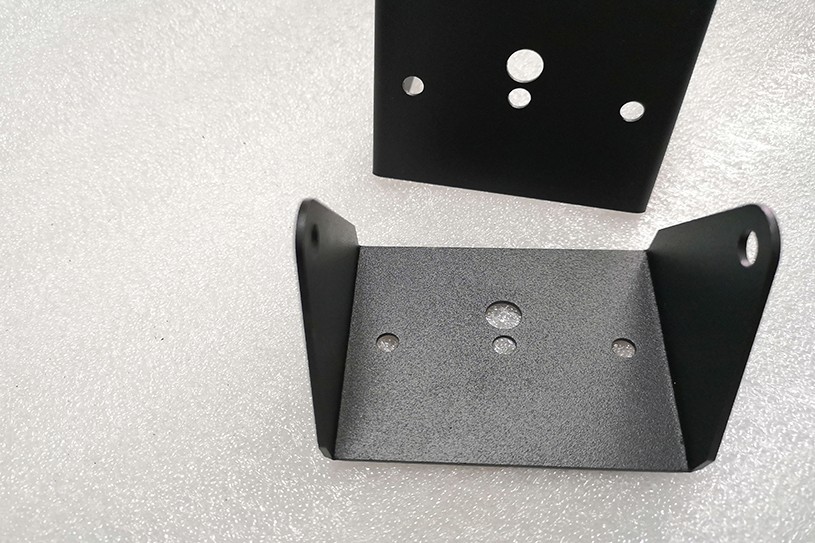

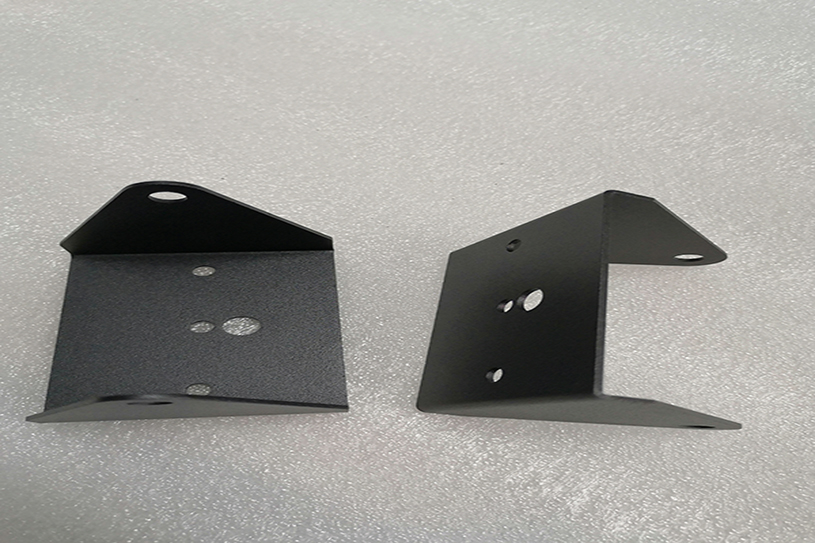

At its core, precision metal stamping is a manufacturing process that utilizes specialized machinery to transform flat metal sheets into precisely shaped components. Unlike traditional methods that rely heavily on molds and dies, precision metal stamping offers unparalleled accuracy, repeatability, and efficiency in creating intricate parts for electronic devices.

Materials Matter

One of the key advantages of precision metal stamping is its versatility in working with various metals. From stainless steel and aluminum to copper and more, manufacturers can choose the ideal material for specific electronic applications, ensuring durability, conductivity, and overall performance.

Accuracy and Consistency

Precision metal stamping excels in producing electronic components with tight tolerances and intricate details. The process ensures that each stamped part is a replica of the others, maintaining consistency critical for the performance of electronic devices.

Cost-Effectiveness

By minimizing material waste and reducing the need for secondary operations, precision metal stamping proves to be a cost-effective manufacturing solution. The efficiency of the process translates into lower production costs without compromising on quality.

Rapid Prototyping

In the fast-paced world of electronics, rapid prototyping is a game-changer. Precision metal stamping allows for quick turnaround times, enabling manufacturers to test and iterate designs at an accelerated pace, ultimately speeding up the product development cycle.

Connectors and Contacts

Custom sheet metal stamping plays a crucial role in the production of connectors and contacts in electronic devices. The high level of precision ensures reliable electrical connections, contributing to the overall functionality of gadgets.

Shielding and EMI Components

As electronic devices become more compact, the need for effective electromagnetic interference (EMI) shielding is paramount. Precision metal stamping enables the creation of intricate shielding components that protect sensitive electronics from external interference.

Micro-Sized Components

In the era of miniaturization, precision metal stamping shines in producing micro-sized components for applications like microelectronics and medical devices. The ability to work with thin materials while maintaining precision is a hallmark of this advanced manufacturing process.

In the evolving landscape of electronic manufacturing, precision metal stamping stands as a cornerstone technology, driving innovation and pushing the boundaries of what's possible. Beyond molds and dies, this comprehensive guide has shed light on the intricacies of precision metal stamping, emphasizing its role in shaping the electronic devices that define our connected world. As technology continues to advance, so too will the precision and capabilities of metal stamping, ensuring a future where electronic components are not just smaller but smarter and more efficient than ever before.