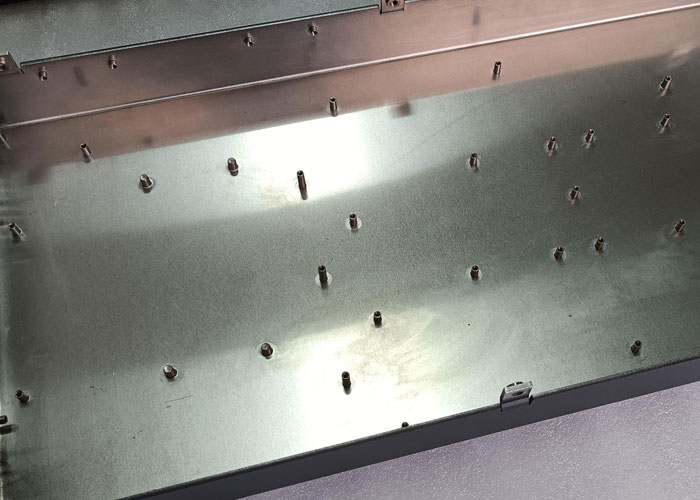

Riveting, also known as rivet connection, which is a mechanical term that uses axial force to thicken the rivet rod in the rivet hole of a component and form a nail head, connecting multiple components together.

Advantages and disadvantages of riveting

Advantage:

High connection strength: Riveting is achieved by inserting rivets into the holes of the part and applying force to deform them, forming a tight connection. This connection method can withstand large loads and is suitable for parts with high strength requirements.

Good stability: Riveted connections will not easily loosen or fall off due to external forces, and can maintain the stability of the connection for a long time. This is important for some parts that require high connection stability.

Strong adaptability: Riveting can connect parts of different materials. Such as stainless steel and aluminum, metal and non-metal, etc. In addition, riveting can also connect complex shaped parts, such as curves, arcs, etc., with high flexibility.

Simple process equipment: The riveting process equipment is relatively simple, easy to operate, and has a faster production speed.

Disadvantage:

High cost of riveting equipment: The riveting process requires specialized equipment, and the cost of riveting equipment is relatively high.

Riveted parts are difficult to disassemble: due to the deformation of the rivet during riveting, it is not easy to disassemble the riveted connection. If it is necessary to disassemble or replace connectors, destructive disassembly is usually required, which can cause damage to the parts and pose certain difficulties for repair and replacement.

Riveting can cause damage to the surface of the metal parts: During the riveting process, it is necessary to drill holes and small scratches on the surface of the parts, which can have a certain impact on the appearance of the part. Therefore, riveted parts usually need to be powder coated to cover up defects after riveting.

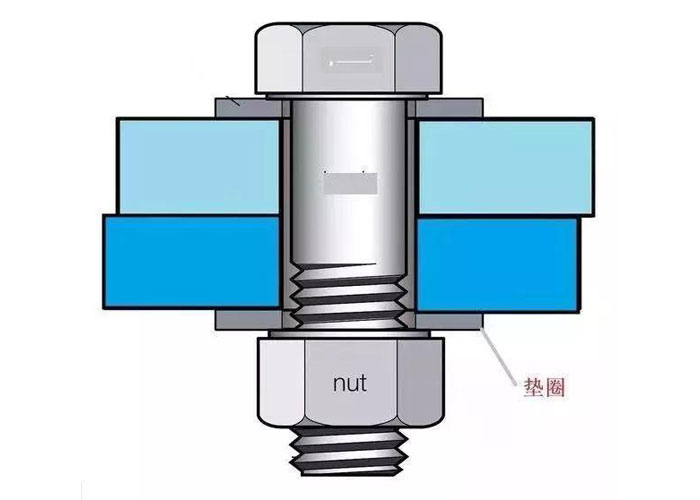

Bolt connection is a mechanical principle that utilizes threaded pairs to fix workpieces through nuts and bolts. Bolt connections have important applications in mechanical engineering and can meet different usage requirements. The basic principles of bolt connection include pre tightening force, bolt tension, and bolt load distribution.

Advantages and disadvantages of bolting

Advantage:

Easy to assemble and disassemble: Due to the gap between the rod and hole of ordinary bolts, the processing requirements are relatively low, which makes the connection process simple. Bolt connections can be easily disassembled for easy inspection and maintenance.

Adjustable preload force: The preload force can be adjusted as needed, with low internal stress and resistance to breakage during vibration.

Stable material composition: Will not cause phase transition of the material composition at the connection.

Wide applicability: Suitable for connections that can withstand tensile and shear forces.

Disadvantages:

Easy to loosen: During use, bolts may loosen and anti loosening measures need to be taken.

Increasing weight: Compared to welding and other connection methods, bolted connections will increase the overall weight of the structure.

Corrosion risk: The gaps in bolted connections are prone to corrosion, which may lead to connection failure.

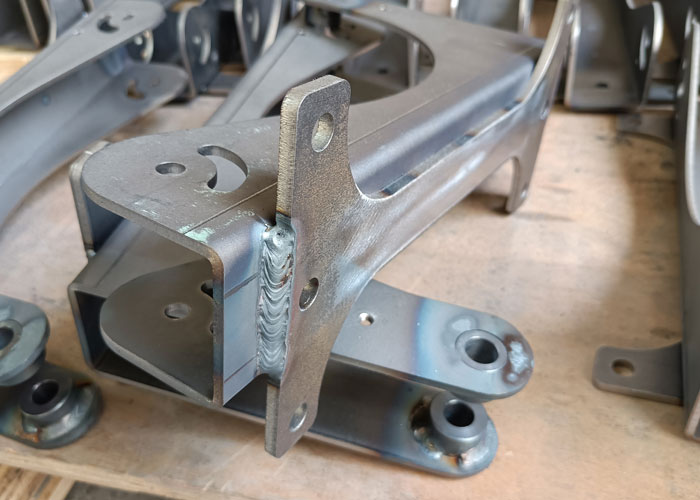

Welding, also known as fusion, is a manufacturing process and technology that involves joining metals or other thermoplastic materials such as plastics through heating, high temperature, or high pressure.

Advantages and disadvantages of welding

Advantage:

High connection stability: Welding is a metal processing technology that melts metal materials through the conduction of thermal energy and fuses them with other metal materials. Compared with other connection methods, welding can form a larger contact area on the connection surface, thus having better firmness and seismic resistance.

Good sealing: During the welding process, the melted metal will fill the gaps and small pores at the connection site, forming a continuous metal connection. This metal connection can prevent the penetration of gases, liquids, and solids, ensuring the normal operation of the parts.

Good conductivity and thermal conductivity: During the welding process, metal materials melt and fuse together at high temperatures, forming a continuous metal conductor that can effectively conduct current and heat.

Good appearance quality: The welded joints can be flush with the surface of the parts, and the shapes of the welded joints are diverse, which can meet the needs of different structures and shapes. Welding can also repair and improve the surface of the parts, improve the quality and flatness of the metal part surface, and enhance the overall appearance quality of the part.

Disadvantages:

Non removable structure: Welding structures are inconvenient for replacement and maintenance.

Stress and deformation: Stress and deformation are easily generated during the welding process, which may lead to welding defects.

When choosing between riveting and screw connections, please consider factors such as material, strength, ease of installation, and whether the connection is permanent or adjustable. Riveting is an ideal choice for structural applications that require strength, durability, and seismic resistance, while bolting have multifunctionality, reusability, and cost-effectiveness, while welding has better strength.