Bend springback refers to the phenomenon in which a metal sheet's bending angle decreases due to its own elastic recovery after the bending force is released. For example, if the target bend angle is 90°, the actual angle after springback may be 91° or 88°, depending on the material and processing conditions.

Springback is a physical phenomenon caused by the elastic nature of metal materials, and is particularly noticeable when bending high-strength steel, aluminum alloys, and thin sheet metal.

High Elastic Modulus of the Material

Metal materials undergo elastic deformation when subjected to external forces and partially recover to their original shape after the force is removed. The higher the elastic modulus of a material, the more pronounced the springback. For example, aluminum alloys typically exhibit more pronounced springback than mild steel.

Relationship between Sheet Thickness and Bending Radius

Thick sheets or those with small bending radii are more susceptible to significant springback. The thicker the sheet and the smaller the bending radius, the greater the springback torque, leading to increased angular deviation.

Improper Processing Parameters

Excessive Bending Speed: Rapid bending can cause stress concentration in the material, increasing springback.

Improper Die Selection: Inappropriate matching of the bending die radius and opening width with the sheet thickness can exacerbate springback.

Internal Material Stress

Residual stresses may form within the sheet during rolling or cold working. When bending, these stresses release and cause additional springback.

The degree of springback varies greatly among different metal materials, primarily depending on their elastic modulus, strength, and hardening characteristics. Common materials prone to springback include:

Aluminum: Aluminum has a low elastic modulus but high strength aluminum alloys (such as 6061 and 7075) experience significant springback during bending, requiring additional bending compensation.

High-strength steel (HSS/SHS): High-strength steel has a high yield strength and a long elastic phase, resulting in significant springback after bending, especially when bending thin sheets.

Stainless steel: Austenitic stainless steels, especially those (such as 304 and 316), have good plasticity but high elastic recovery, resulting in significant springback. Therefore, additional bending allowance is often required during processing.

Titanium: Titanium has high hardness and high springback, placing extremely high demands on tooling and processing, making it difficult to form in one go.

Copper alloys with good elasticity but high hardness: Beryllium copper alloys have high elastic recovery and are prone to springback.

The higher the material strength, the larger the elastic modulus or the thinner the sheet, the more obvious the springback phenomenon. In the bending process, such materials require more precise bending compensation and mold design.

Inaccurate part dimensions lead to assembly difficulties

Increased processing costs and the need for secondary corrections

The impact is particularly significant on high-precision products (such as chassis and aviation parts).

Choose the Right Material and Plate Thickness

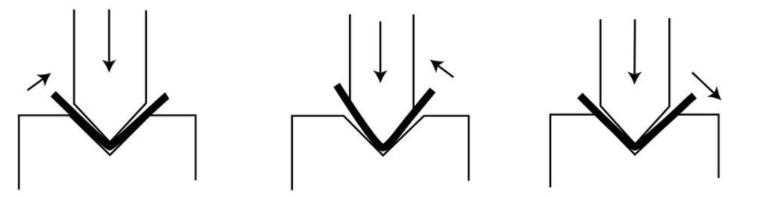

For materials with high springback, increase the bending angle appropriately to bring the final angle closer to the target value.

For thick plates, select an appropriate bending radius to minimize the impact of springback.

Adjust Bending Process Parameters

Bending Slowly: Reduce the bending speed to evenly distribute stress and reduce springback.

Increase Bend Allowance: Reserve an angle based on the material's springback coefficient, commonly known as "bend compensation."

Optimize Mold Design

The mold's/tool’s internal angle should be slightly smaller than the target angle to offset springback.

For high-precision parts, use a bending mold with a push-off or deep-draw assist feature to improve angle control accuracy.

Stress Relief

For plates with residual stress, annealing or vibration stress relief can be performed to reduce springback.