The process of using modern techniques from disciplines such as physics, chemistry, metallurgy, and heat treatment to alter the surface condition and properties of parts, optimizing their combination with core materials to achieve predetermined performance requirements, is called surface treatment.

The role of surface treatment:

Improve surface corrosion resistance and wear resistance, slow down, eliminate, and repair surface changes and damages of materials.

Enable ordinary materials to obtain surfaces with special functions.

Save energy, reduce costs, and improve the environment.

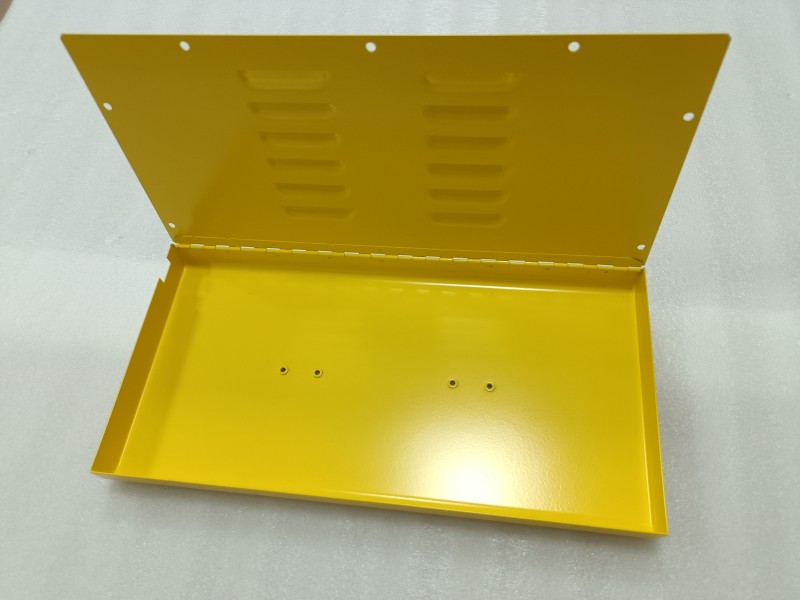

Powder coating is the process of using powder coating equipment to paint powder coating onto the surface of a metal part. Under the action of static electricity, the powder will uniformly adsorb onto the surface of the part, forming a powdery coating; The powder coating undergoes high-temperature baking, leveling, and solidification to become the final coating with different effects (different types of effects of powder coatings).

|  |

|  |

Powder coating has low cost, strong corrosion resistance, beautiful appearance, storage resistance, and can also be customized with a variety of colors and surface effects. It is usually the first choice for most customers.

A process that uses compressed air as a power source to impact the surface of a metal parts with high-speed sand or iron particles, in order to improve the mechanical properties of the part and change the surface state. It can also achieve the purpose of cleaning or modification.

Similar to sandblasting, steel pellets are used instead of sand particles. The cold working process of using pellets to bombard the surface of the metal parts and implant residual compressive stress to enhance the fatigue strength of the metal parts

It’s a surface treatment method that forcibly passes metal through a mold under external force, compresses the cross-sectional area of the metal, and obtains the required cross-sectional area shape and size.

Eliminate scratches on the surface of stainless steel/aluminum plate raw materials and also have a good decorative effect

Anodizing is common in various aluminum products, which requires immersing aluminum or aluminum alloy parts in an acidic electrolyte, acting as an anode under the action of external current, to form a corrosion-resistant oxide film layer firmly bonded to the substrate on the surface of the metal parts, in order to achieve protective, decorative, insulating, and wear-resistant properties.

Clear anodized

In addition to clear anodizing, other colors such as black, gold, and red can also be customized and anodized.

It is a process of depositing a thin layer of zinc on a metal surface through electric current, aimed at enhancing the corrosion resistance and appearance of the metal. It is a popular surface treatment method that can effectively protect metal objects from corrosion and extend their service life.

Zinc plating not only prevents steel from being corroded, but also enhances its decorative appearance.