CNC billet aluminum machined parts have wide applications in the medical field. When medical instruments and implants require precision machining, using CNC billet aluminum machined parts is an excellent choice. They are not only cost-effective but also ensure high precision and good module consistency.

In medical component processing, implant manufacturing is one of the important areas. For example, knee joints and bone implants require extremely high precision and compatibility. CNC billet aluminum machined parts can complete the assembly of implants based on models provided by doctors. Aluminum alloy is lightweight, corrosion-resistant, and biocompatible, making it an excellent implant material.

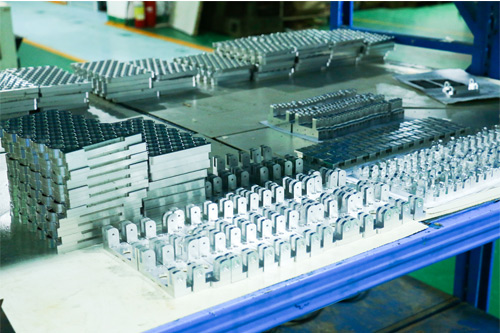

Surgical instruments require precision and good complementarity to ensure the accuracy of surgical operations. CNC billet aluminum machined parts fully meet these requirements. Whether it's surgical blades, scalpels, or aluminum drive systems, automated processing systems ensure high precision and durability of surgical instruments.

In the dental field, CNC billet aluminum machined parts also play an important role. The manufacture of dental implants and orthodontic devices relies on precision machining technology to ensure personalized fit and durability. After obtaining patient oral data through digital scanning technology, CNC machine tools can accurately machine dental implants or orthodontic device brackets that meet patient needs. The lightweight and corrosion resistance of aluminum make it an ideal choice for dental instruments.

In addition, probes, drills, and other instruments required for dental surgery also rely on the high precision of CNC machining to ensure safety and precision in operation. CNC billet aluminum machined parts can manufacture complex structures that meet medical standards, further improving the success rate of dental surgeries.

Electrocardiographs, MRIs, and X-ray machines contain many precision mechanical parts. CNC billet aluminum machined parts play a significant role in these devices, such as in the manufacture of control handles, buttons, and housings. The glossy effect and wear resistance of aluminum alloy ensure the safety and reliability of devices when involving human operation.

In conclusion, CNC billet aluminum machined parts play a core role in the medical field. Whether it's implants, surgical instruments, dental implants or orthodontic devices, or medical electronic devices, automated systems and high-precision machining capabilities ensure the quality and safety of products. Additionally, to highlight the advantages of auxiliary equipment, it is recommended to use automated systems and professional precision equipment in conjunction.