What surface treatments can be done on metal parts to achieve insulation effect?

In the fields of electronics, electrical, and industrial manufacturing, metal parts often require electrical insulation to avoid short circuits, electrical leakage, and safety accidents. Through different surface treatment processes, an insulating layer can be formed on the metal surface, thus balancing mechanical strength and electrical safety.

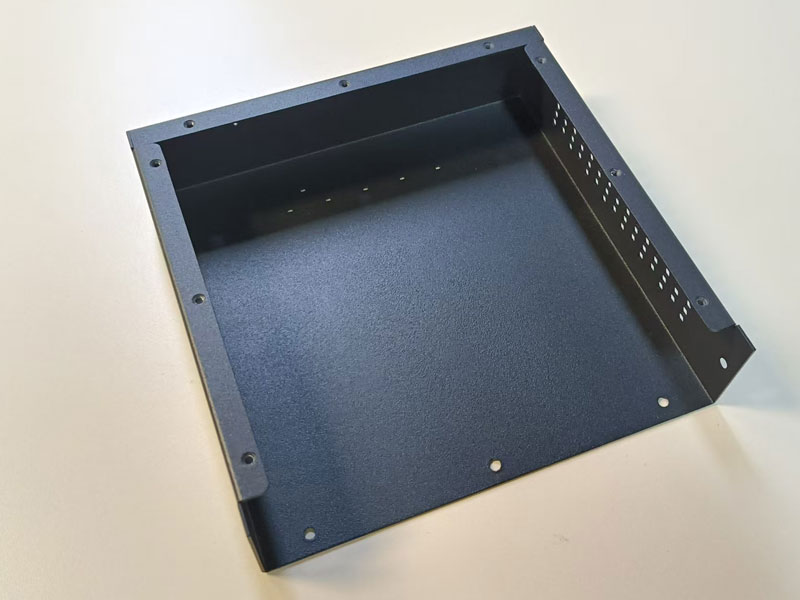

Spray thermosetting insulation powder (epoxy, polyester, etc.) using the principle of electrostatic adsorption, and form a dense and uniform insulation coating after heating and curing.

Advantage

Large coating thickness (60-120 μ m), good insulation and voltage resistance

Corrosion resistant and scratch resistant

Rich surface appearance (multiple colors, gloss)

Environmentally friendly solvent-free

Disadvantage

Limited coverage for complex shaped holes and slots

Strict pre-treatment requirements (thorough removal of oil and rust)

Once locally damaged, insulation may be lost

Typical applications

Electrical casing, chassis rails, electrical accessories

The metal parts are subjected to direct current in the electrophoresis tank, and the insulating resin is uniformly deposited and attached.

Advantage

Uniform membrane layer and strong permeability

Good coverage of complex structures and pores

High degree of production automation and efficiency

Disadvantage

The weather resistance is average, and subsequent spraying is needed to improve corrosion resistance

The membrane layer is relatively thin (15-30 μ m)

The cost of investing in equipment is relatively high

Typical applications

Automotive parts, power tool components, small hardware components

process description

Mainly used for aluminum, it generates an aluminum oxide layer through electrochemical reactions.

Advantage

The oxide film has high hardness and good insulation properties

Corrosion resistant and wear-resistant

flaking

Disadvantage

Only applicable to aluminum and its alloys

Thin film layer (ordinary anodizing<20 μ m) requires thickening process

Easily corroded by alkaline substances in certain environments

Typical applications

Aluminum shell, heat sink, electrical bracket

After preheating, the metal is immersed in PVC or PE powder and melted to form a closed coating.

Advantage

High coating thickness (200-500 μ m) with outstanding insulation properties

Soft surface feel

Impact resistant and moisture resistant

Disadvantage

Easy to age and deform in high temperature environments

Limited color selection

Preheating equipment is required for the process

Typical applications

Tool handle, cable bracket, protective sheath metal parts

Spray insulation type epoxy, polyurethane or silicone resin paint, and form a thin film after curing.

Advantage

Flexible and applicable to complex geometric shapes

Convenient construction and simple maintenance

Suitable for small batches or repairs

Disadvantage

Thin film layer (20-50 μ m) is prone to wear and tear

Solvent based paint has poor environmental friendliness

Durability depends on the type of paint and curing process

Typical applications

Motor iron core, electrical components, coil skeleton

Insulation films such as polyimide (PI) and polyester (PET) are bonded or heat pressed together.

Advantage

High temperature resistance and high insulation voltage (thousands of volts)

Thickness controllable (tens to hundreds of micrometers)

Repackable and replaceable

Disadvantage

Multiple manual operation processes

The adhesive layer may fail in humid environments

High cost

Typical applications

High frequency circuit base, medical equipment components

High temperature plasma arc sprays ceramic materials such as alumina onto metal surfaces.

Advantage

Excellent insulation performance

High temperature resistance and chemical corrosion resistance

High hardness and wear resistance

Disadvantage

Complex process and high cost

The coating is brittle and prone to cracking

Not suitable for flexible applications

Typical applications

Electric heating components, insulation flanges, high-temperature electrical components