Anodizing is a process that uses electrolysis to create a stable oxide film on a metal surface. It's commonly used on aluminum. By passing electricity through a specific electrolyte, with the metal workpiece acting as the anode, a dense, hard oxide film forms on the surface.

This film not only offers excellent corrosion resistance, hardness, and insulation properties, but it can also be customized with various colors and surface textures.

1. Aluminum

The most suitable metal for anodizing, with a mature process and widespread application.

It forms a dense, hard, and highly adhesive oxide film.

It supports a variety of surface treatments (mirror, brushed, sandblasted, etc.) before anodizing.

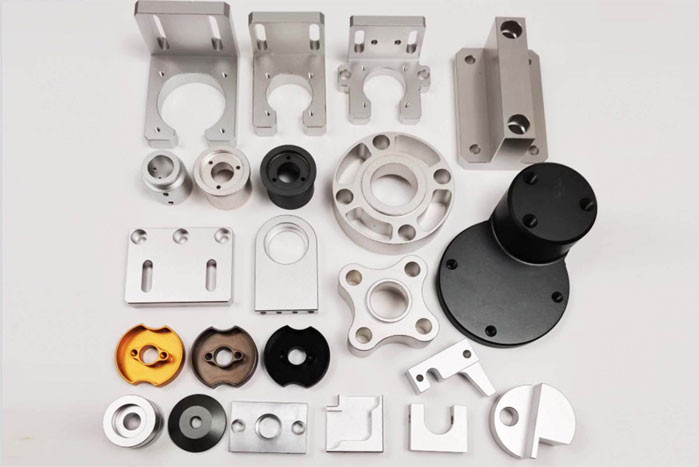

Applications: 3C electronic product casings, architectural profiles, and sheet metal components.

2. Titanium and its alloys

The film exhibits excellent biocompatibility and corrosion resistance.

Applications: Medical devices, eyeglass frames, watch accessories, and high-end industrial parts.

3. Magnesium and its alloys

Magnesium is a light metal, and an anodized film can enhance its corrosion resistance.

However, the film is porous and less dense, requiring a sealing treatment.

Applications: Lightweight components and aerospace structures.

Metals Not Suitable for Anodizing: Stainless steel, copper, carbon steel, and other metals are not suitable for anodizing due to their surface passivation or electrochemical properties. Instead, other surface treatments such as electroplating, spraying, and passivation are often used.

For example, mirror polishing, brushing, and passivation are often used instead of anodizing for stainless steel.

Improved Corrosion Resistance: Anodizing forms a dense oxide film on the metal surface, effectively preventing oxidation and rust, making it particularly suitable for use in humid or corrosive environments.

Enhanced Surface Hardness and Wear Resistance: The oxide layer is typically quite hard (especially with hard anodizing), significantly improving scratch and friction resistance.

Improved Decorative Properties: Available in a variety of colors (such as black, silver, gold, red, and blue), it is suitable for applications requiring high aesthetics.

Excellent Electrical Insulation: The anodized layer is non-conductive, making it suitable for electronic equipment components requiring electrical insulation.

Environmentally Friendly: Compared to processes such as electroplating, the chemicals used in anodizing are relatively environmentally friendly and contain no heavy metals.

Strong Coating Adhesion: The oxide film is integral to the metal substrate, resisting peeling and flaking, and offering excellent durability.

This is one of the most important questions in actual production. We will address this in detail from two perspectives:

Welding after anodizing is not recommended for the following reasons:

The oxide film is insulating and can hinder current conduction, resulting in arc failure or unstable welding.

The film can burn under high temperatures, forming black spots that affect weld quality and appearance.

Once the anodized film is damaged, the overall corrosion protection will be affected.

If welding is required, weld first and then anodize. The weld seam should be polished and smoothed before anodizing.

Anodized metal surfaces become harder but also more brittle. Therefore:

Bending can easily cause the film to crack, peel, or dust.

Excessive bending can cause stress concentration on the inside, leading to breakage or discoloration.

The appearance will be severely affected, making it unsuitable for parts with high aesthetic requirements.

Sheet metal parts should be bent and formed before anodizing to ensure a continuous and complete coating and avoid subsequent defects.

Anodizing is an excellent surface treatment process, particularly widely used in aluminum sheet metal processing. However, it's not a panacea—if welding or bending is planned on the product, these processes must be completed before anodizing to ensure both functionality and aesthetic quality.

HSJ, an excellent name in China aluminum sheet metal fabrication, excels in anodizing, an excellent surface treatment process widely used in aluminum sheet metal processing.